Our team is highly trained and experienced in servicing and producing all types of steel supplies. Need help or have a question?

sales@abrasionresistantpipe.com

Tel.: +8621-3378-0199

Our team is highly trained and experienced in servicing and producing all types of steel supplies. Need help or have a question?

sales@abrasionresistantpipe.com

Tel.: +8621-3378-0199

Standard cast basalt tile is made from natural basalt rocks that are melted and poured into molds to create different shapes and sizes.

Standard cast basalt tile is made from natural basalt rocks that are melted and poured into molds to create different shapes and sizes. Standard cast basalt tiles typically measure 10x10cm or 15x15cm and can have thicknesses ranging from 15mm to 60mm. The tiles are known for their exceptional hardness, abrasion resistance, and chemical inertness, making them an ideal material for lining surfaces that are exposed to demanding conditions. They are also non-conductive, non-magnetic, and non-sparking, making them a popular choice for use in explosive environments. Standard cast basalt tiles are commonly used in mining, cement, steel, power generation, and other heavy industries.

Standard cast basalt tiles are a type of construction material that is made from melted basalt rock and then poured into molds where it is left to cool and solidify. During this process, the melted basalt rock is transformed into a highly abrasion-resistant and durable tile that can be used in a variety of applications.

Standard cast basalt tiles typically have a hexagonal shape and are available in various sizes and thicknesses. They are often used in industries such as mining, cement manufacturing, and power generation, where machinery and equipment are subject to high levels of wear and tear.

Features and benefits of standard cast basalt tiles include:

In conclusion, standard cast basalt tiles are a durable and abrasion-resistant construction material that are used in various industries where machinery and equipment are exposed to high wear and corrosion. With their high resistance to abrasion and chemicals, low coefficient of friction, and ease of installation, these tiles offer a reliable and cost-effective solution that can significantly reduce long-term maintenance costs.

Standard cast basalt tiles are used in a wide range of industrial applications where high levels of abrasion, corrosion or impact are present. Some common applications include:

In addition, standard cast basalt tiles can be used in many other industries, including wastewater treatment, pulp and paper manufacturing, food processing, and pharmaceuticals.

In conclusion, standard cast basalt tiles are widely used in various industries where equipment is exposed to high levels of abrasion, corrosion, or impact. With their excellent resistance to wear and tear, chemicals, and thermal shock, these tiles provide a reliable and cost-effective solution to reduce maintenance costs and downtime.

| 200*200*14 | H190*40 |

| 200*200*40 | H200*30 |

| 200*300*14 | H247*30 |

| 200*300*50 | H250*30 |

| 210*240*30 | 300*75*30 条 |

| 400*200*40 | 300*90*50 条 |

| 400*300*20 | 300*75*45 条 |

| 400*500*60 | 300*100*50 条 |

Cast basalt pipes owing to an excellent performance of abrasive and corrosion resistance .It may be used as the liner of pipeline for hydraulic,pneumatic of conveyance of material and corrosion materials or slurry.We can offer the basalt pipes with nominal diameter of 40mm-800mm.

Cast Basalt can be used for the lining of pipework, chutes, bunkers, cyclones, and hoppers. It has become the global standard in areas such as ash slurry pipework, often used at fossil-fuel power stations. It is an all-round cost-effective and adaptable lining material that extends the life of equipment in the pipe or tile form where affected by erosion.

Cast Basalt is well-proven in a variety of industries as a cost-effective, long-lasting lining material used to extend the operating life of equipment manufactured or lined with lower-wearing materials such as steel, cast iron, rubber, and polyurethane.

Cast basalt lined steel pipe, as both a wear—resistant and corrosion—resistant materials, the transport properties of wear or corrosion of materials, after thirty years of practical verification, cast basalt lined steel pipe can be well done.

Cast basalt is also used in cement plants for making air separators, chain conveyor, silica hoppers, nozzles, coal hoppers, cement hoppers, cyclones, raw mill ducts, chutes, thick slurry lines, mixers, grate cooler housing, coal ventury etc.

Cast basalt pipes have an excellent performance of abrasive resistant and corrosion resistant, can be used as the pipeline lining in conveying wearable materials and corrosion materials. Such as: electric power plant, chemical plant, metallurgy industry, mine and so on.

Cast Basalt Composite Pipes Used for Years

Cast basalt pipe adopts foam packaging, then in accordance with the specifications to put them into wooden cases, sometimes they can be directly loaded into the compartment or container.

Cast basalt pipe adopts foam packaging, then in accordance with the specifications to put them into wooden cases, sometimes they can be directly loaded into the compartment or container.

Cast basalt lined pipes and fittings can be supplied with different and connections as per the design requirement to suit the site conditions and easy installation.

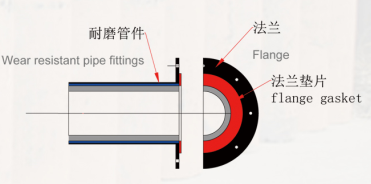

As a standard production, we supply flanged components according to DIN, with at least one movable flange for easy mounting, but pipes with plain ends or for custom coupling are also available. Flange Connection Is One Kind Of Common Pipeline Installation Connections. By Two Pieces Of Flanges, Pipeline, Valve, Equipments Are Connected And It Forms A Tight Piping System. When Pipeline Pressure Is Larger, Flange Connection Is Priority Selection. Flanges Have Lots Of Different Sizes. Flange Size Is Determined According To Pipeline Normal Diameter And Pipeline Operation Pressure.

The parameters of the outside steel pipe will be decided according to the working pressure of the system. The connection of the pipes and fitting will be of flange connections, easy—flexible joint connection or by welding.

By two pieces of flanges, pipeline, valve, equipments are connected and it forms a tight piping system. When pipeline pressure is larger, flange connection is priority section. Flanges have lots of different sizes.

Flange size is determined according to pipeline normal diameter and pipeline operation pressure.

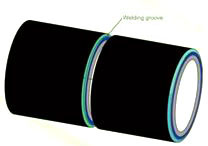

It suits short Distance Pipeline System Without Maintenance. It Is One Kind Of Common Installation Connections. It Requires Installation Personnel Higher Welding Ability. It Also Restricts By Welding Site, Distance, Welding Positions. Welding Connections Is Inconvenient In Later Maintenance.

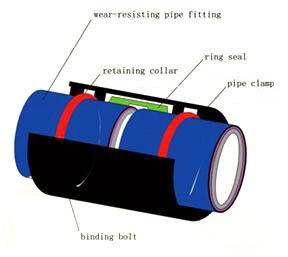

It Is One Of High Efficient And Rapid Installation Connection. I T Has The Below Characteristic: Easily Install And Disassemble, Fast Installation, Temperature Adjustable Compensation Function, Saving The Necessary Expansion In Long Pipeline. Easy-Flexible Joint Also Has Angle Compensation Characteristic. At Smaller Angle Turning Points, Easy-Flexible Joint Can Be Instead Of Bends And Adjust Angle.

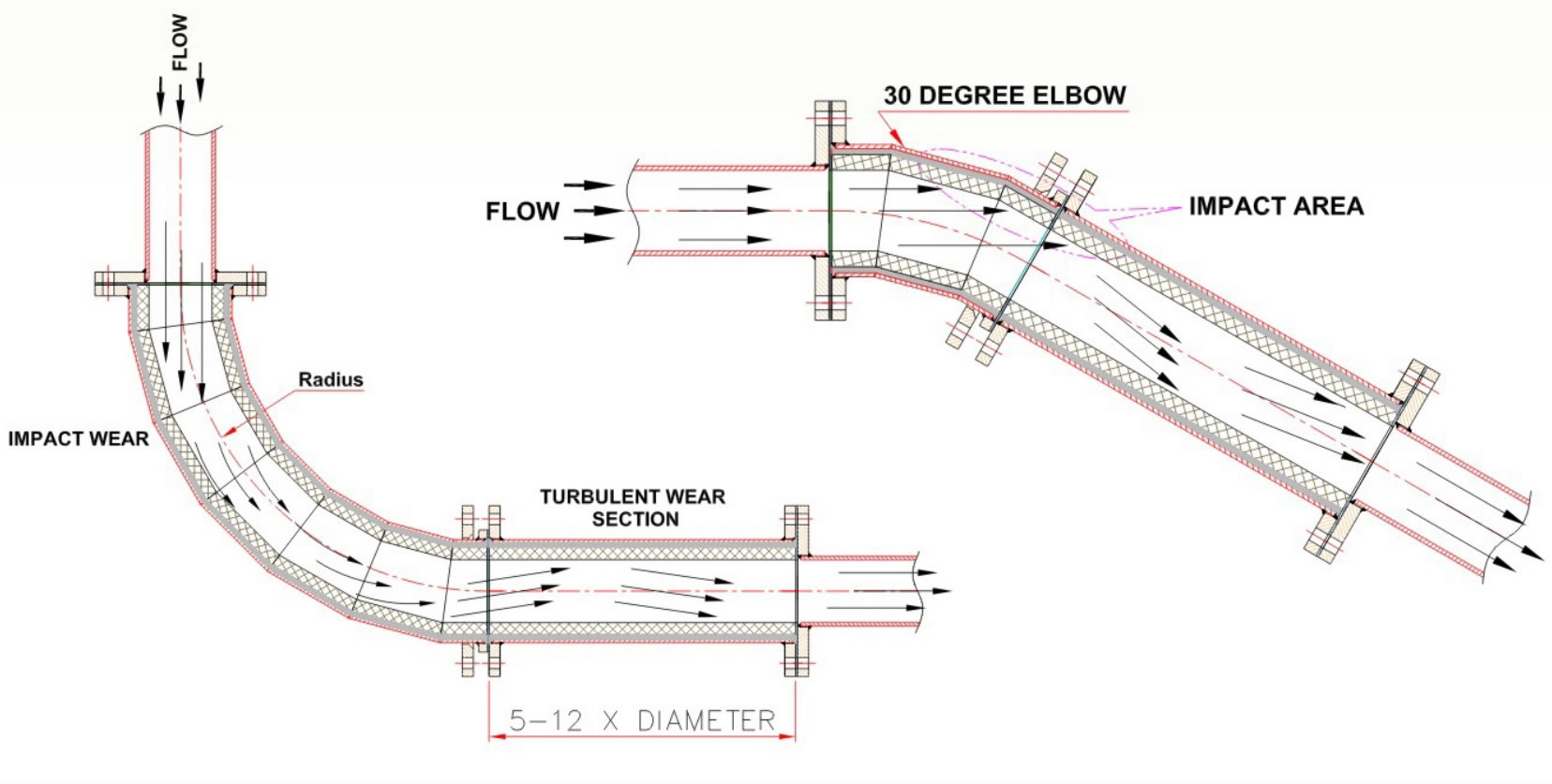

1. The bend radius should be minimum 3 times of the nominal bore.

2. At discharge end of each bend, cast basalt lined straight pipe of length 5 to 12 times the nominal bore must be used.

Need to inquire about our products? Fill out the form below and our staff will be in touch!

Q: How long is your delivery time?

A: The delivery time of customized products is generally 25 35 days, and non customized products are generally shipped within 24 hours after payment.

Q: Do you provide samples? Is it free?

A: If the value of the sample is low, we will provide it for free, but the freight needs to be paid by the customer. But for some high value samples, we need to charge a fee.

Q: What are your payment terms?

A: T/T 30% as the deposit,The balance payment is paid in full before shipment

Q: What is the packaging and transportation form?

A: Non steaming wooden box and iron frame packaging. Special packaging is available according to customer needs. The transportation is mainly by sea.

Q: What is your minimum order quantity?

A: There is no minimum order quantity requirement. Customized products are tailor made according to the drawings provided by the customer.