Our team is highly trained and experienced in servicing and producing all types of steel supplies. Need help or have a question?

sales@abrasionresistantpipe.com

Tel.: +8621-3378-0199

Our team is highly trained and experienced in servicing and producing all types of steel supplies. Need help or have a question?

sales@abrasionresistantpipe.com

Tel.: +8621-3378-0199

The pressureless sintered silicon carbide thermocouple protection tube has the characteristics of oxidation resistance, high thermal conductivity, corrosion resistance, thermal shock resistance and excellent high temperature strength, etc., It can withstand high temperature and the erosion of strong corrosive substances, which is the best material for making thermocouple protection tube.

The pressureless sintered silicon carbide thermocouple protection tube has the characteristics of oxidation resistance, high thermal conductivity, corrosion resistance, thermal shock resistance and excellent high temperature strength, etc., It can withstand high temperature and the erosion of strong corrosive substances, which is the best material for making thermocouple protection tube. Silicon carbide thermocouple protection tube is usually used with the thermocouple, thermostat, thermometer, etc., mainly for protecting the sensor from being damaged by external forces, preventing the internal components from being corroded by harmful substances in the environment, and quickly and accurately transferring heat energy. Silicon carbide has a strong ability in heat resistance, oxidation resistance, heat shock resistance, wear-resistance and chemical stability, etc. It is an ideal material for a high-performance thermocouple protection tube.

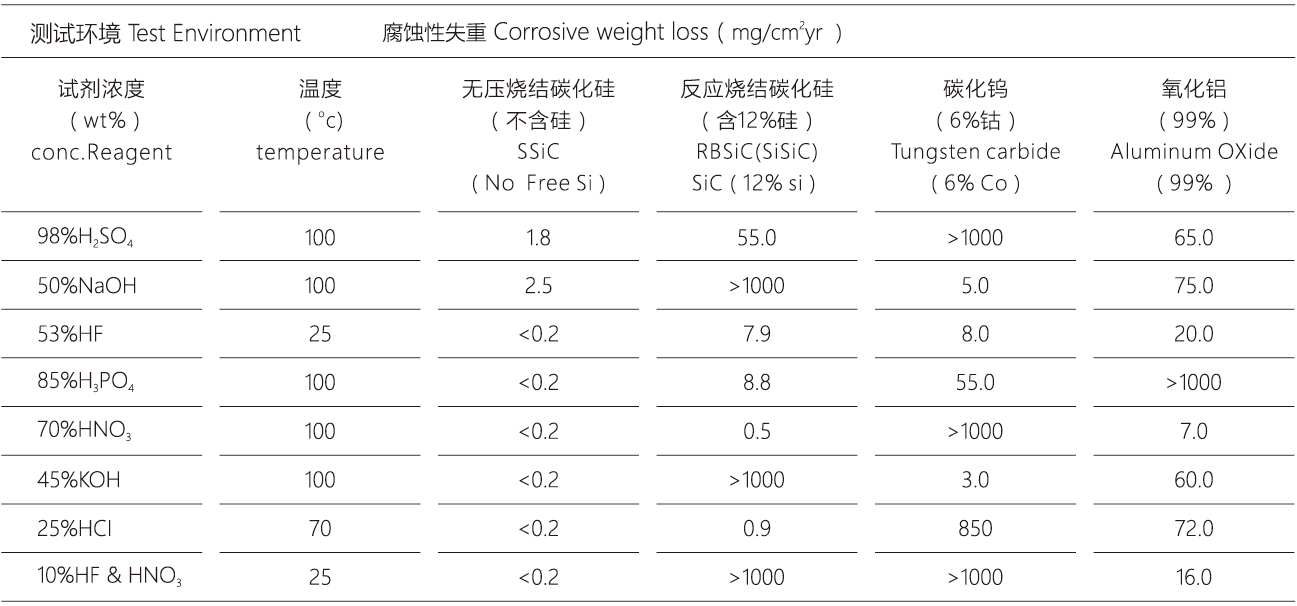

At present, there are two series silicon carbide products of pressureless sintering silicon carbide (SSIC) and reaction sintering silicon carbide (SISIC), which are widely used in mining, metallurgy, chemical industry, electric power, petroleum, furnace, machinery, steel, energy, environmental protection, building materials, semiconductor, aerospace and other fields. Compared with reaction bonded silicon carbide, pressureless sintered silicon carbide has higher purity, better mechanical properties, more prominent corrosion resistance(Resistant to strong acid and alkali corrosion, It is also the only ceramic material which can resistant to hydrofluoric acid corrosion), higher wear resistance, because of there’s no free silicon in the material. It can be used longer service life in environments which other materials not meet.

Silicon carbide (SiC) is a lightweight ceramic material with high strength properties comparable to diamond. It has excellent thermal conductivity, low thermal expansion, and is resistant to acid corrosion. Silicon carbide is an excellent ceramic material suitable for applications requiring good corrosion resistance and wear resistance.

Silicon carbide is formed in two ways, reaction bonding and sintering. Each forming method greatly affects the end microstructure.

Reaction bonded SiC is made by infiltrating compacts made of mixtures of SiC and carbon with liquid silicon. The silicon reacts with the carbon forming more SiC which bonds the initial SiC particles.

Sintered SiC is produced from pure SiC powder with non-oxide sintering aids. Conventional ceramic forming processes are used and the material is sintered in an inert atmosphere at temperatures up to 2000ºC or higher.

Both forms of silicon carbide (SiC) are highly wear resistant with good mechanical properties, including high temperature strength and thermal shock resistance. Our engineers are always available to best advise you on the strengths and weaknesses of each ceramic for your particular needs.

The crystal structure of the SiC ceramic wear-resistant pipe is similar to that of the diamond tetrahedral structure. It is a compound composed mainly of covalent bonds. Its hardness is high (Mohs 9.3), its performance is stable, and its physical properties are similar to diamond. It is also known as emery. Black silicon carbide crystal Hardness is the second-order material for diamonds. It is mainly used for making abrasives and grinding wheels, and partly for the production of silicon carbide ceramics.

![]()

Silicon carbide ceramics are widely used not only in industry, but also in other fields. So, what should be paid attention to when using silicon carbide ceramics?

The hardness of silicon carbide ceramics is very strong, although it does not look as eye-catching as other ceramics, but the use of ornamental ceramics is incomparable. In the process of use, as long as you follow the instructions, there is no need to pay special attention to. Just keep it clean.

If the method used is not correct, the silicon carbide ceramics will be damaged. We can extend its service life by regular maintenance.

Silicon carbide (SiC) is a lightweight ceramic material with high strength properties comparable to diamond. It has excellent thermal conductivity, low thermal expansion, and is resistant to acid corrosion. Silicon carbide is an excellent ceramic material suitable for applications requiring good corrosion resistance and wear resistance.

Comparison of parameters of silicon carbide ceramic products of different materials

![]()

Liquid corrosion test data for different materials

Remarks

Our silicon carbide tube and fitting is carefully handled to minimize damage during storage and transportation and to preserve the quality of our products in their original condition. We guarantee intact during transportation, loading and unloading, and have measures to reduce vibration and impact, so as to ensure the integrity of the product during transportation.

Our silicon carbide tube and fitting is carefully handled to minimize damage during storage and transportation and to preserve the quality of our products in their original condition. We guarantee intact during transportation, loading and unloading, and have measures to reduce vibration and impact, so as to ensure the integrity of the product during transportation.

![]()

![]()

Need to inquire about our products? Fill out the form below and our staff will be in touch!

Q: How long is your delivery time?

A: The delivery time of customized products is generally 25 35 days, and non customized products are generally shipped within 24 hours after payment.

Q: Do you provide samples? Is it free?

A: If the value of the sample is low, we will provide it for free, but the freight needs to be paid by the customer. But for some high value samples, we need to charge a fee.

Q: What are your payment terms?

A: T/T 30% as the deposit,The balance payment is paid in full before shipment

Q: What is the packaging and transportation form?

A: Non steaming wooden box and iron frame packaging. Special packaging is available according to customer needs. The transportation is mainly by sea.

Q: What is your minimum order quantity?

A: There is no minimum order quantity requirement. Customized products are tailor made according to the drawings provided by the customer.