Our team is highly trained and experienced in servicing and producing all types of steel supplies. Need help or have a question?

sales@abrasionresistantpipe.com

Tel.: +8621-3378-0199

Our team is highly trained and experienced in servicing and producing all types of steel supplies. Need help or have a question?

sales@abrasionresistantpipe.com

Tel.: +8621-3378-0199

We produce sintered SiC tubes, reaction bonded SiC tubes and recrystallized SiC tubes. Our recrystallized SiC products have high purity, while our reaction bonded and sintered silicon carbide balls have high mechanical strength. Our silicon carbide tubes possess good wearability, a low thermal expansion coefficient, extreme corrosion resistance, high hardness and self-lubricating properties. For further information on our silicon carbide and how this can be used for your product, contact us today.

We produce sintered SiC tubes, reaction bonded SiC tubes and recrystallized SiC tubes. Our recrystallized SiC products have high purity, while our reaction bonded and sintered silicon carbide balls have high mechanical strength. Our silicon carbide tubes possess good wearability, a low thermal expansion coefficient, extreme corrosion resistance, high hardness and self-lubricating properties.

Silicon carbide (SiC) is a lightweight ceramic material with high strength properties comparable to diamond. It has excellent thermal conductivity, low thermal expansion, and is resistant to acid corrosion. Silicon carbide is an excellent ceramic material suitable for applications requiring good corrosion resistance and wear resistance.

Silicon carbide is formed in two ways, reaction bonding and sintering. Each forming method greatly affects the end microstructure.

Reaction bonded SiC is made by infiltrating compacts made of mixtures of SiC and carbon with liquid silicon. The silicon reacts with the carbon forming more SiC which bonds the initial SiC particles.

Sintered SiC is produced from pure SiC powder with non-oxide sintering aids. Conventional ceramic forming processes are used and the material is sintered in an inert atmosphere at temperatures up to 2000ºC or higher.

Both forms of silicon carbide (SiC) are highly wear resistant with good mechanical properties, including high temperature strength and thermal shock resistance. Our engineers are always available to best advise you on the strengths and weaknesses of each ceramic for your particular needs.

The crystal structure of the SiC ceramic wear-resistant pipe is similar to that of the diamond tetrahedral structure. It is a compound composed mainly of covalent bonds. Its hardness is high (Mohs 9.3), its performance is stable, and its physical properties are similar to diamond. It is also known as emery. Black silicon carbide crystal Hardness is the second-order material for diamonds. It is mainly used for making abrasives and grinding wheels, and partly for the production of silicon carbide ceramics.

Silicon carbide furnace tubes mainly have four application areas: functional ceramics, advanced refractories, abrasives and metallurgical raw materials. However, the application of nano-silicon carbide powder with extremely high technical content cannot form economies of scale in a short period of time. Silicon carbide raw materials can already be supplied in large quantities and cannot be said to be high-tech products. So, let’s take a look at the main features of silicon carbide furnace tubes.

As an abrasive, it can be used for grinding wheels such as whetstone, grinding heads, and sand tiles.

As metallurgical deoxidizer and high temperature resistant material.

It is a high-purity single crystal and can be used for the manufacture of semiconductors and the manufacture of silicon carbide fibers.

Main uses of silicon carbide furnace tubes: engineering processing materials for solar power generation industry, semiconductor industry, piezoelectric crystal industry, and wire cutting of 3-12 inch monocrystalline silicon, polycrystalline silicon, potassium arsenide, quartz crystal, etc.

Silicon carbide furnace tubes can be used in lightning rods, circuit components, high temperature applications, UV light detectors, materials of construction, astronomy, disc brakes, clutches, diesel particulate filters, filament pyrometers, ceramic membranes, cutting tools, heating parts, nuclear fuel, Gems, Steel, Armor, Catalyst

Folding Abrasives

Mainly used for polishing and polishing of grinding wheel, sandpaper, abrasive belt, oil shale, polishing block, polishing head, polishing paste, monocrystalline silicon, polycrystalline silicon in photovoltaic products and piezoelectric crystals in the electronics industry.

Folding “three resistant” material

Using silicon carbide with corrosion resistance, high temperature resistance, high strength, good thermal conductivity, impact resistance and other characteristics, silicon carbide can be used for various smelting furnace linings, high temperature furnace parts, silicon carbide plates, furnace linings, supports, Russian fuel boiler, silicon carbide crucible, etc.

Foldingnon-ferrous metal

Silicon carbide furnace tube has high temperature resistance and high strength, such as hard pot distillation furnace, rectification tower tray, aluminum electrolytic cell, copper furnace lining, electric arc furnace for zinc powder furnace, thermocouple protection tube, etc. Good thermal conductivity, resistance to Impact, used as high temperature indirect heating material.

Folding steel

Using the characteristics of corrosion resistance, thermal shock wear resistance and good thermal conductivity of silicon carbide furnace tubes, it is used for the lining of large blast furnaces to improve the service life.

Metallurgical beneficiation

The hardness of silicon carbide is second only to that of diamond, and its wear resistance is cast iron. With strong wear resistance, it is an ideal material for wear-resistant pipelines, impellers, pump rooms, cyclones, and pipelines. Def with 5–20 times the life of rubber is also one of the ideal materials for flight lines.

Folding building materials ceramic grinding wheel industry

Using its characteristics of thermal conductivity, heat radiation, high thermal strength, and can improve the filling capacity and product quality of the kiln, shorten the production cycle, the manufacture of thin-plate kiln furniture can not only reduce the capacity of the kiln furniture, it is an ideal indirect material for ceramic enamel sintering .

![]()

Silicon carbide ceramics are widely used not only in industry, but also in other fields. So, what should be paid attention to when using silicon carbide ceramics?

The hardness of silicon carbide ceramics is very strong, although it does not look as eye-catching as other ceramics, but the use of ornamental ceramics is incomparable. In the process of use, as long as you follow the instructions, there is no need to pay special attention to. Just keep it clean.

If the method used is not correct, the silicon carbide ceramics will be damaged. We can extend its service life by regular maintenance.

Silicon carbide (SiC) is a lightweight ceramic material with high strength properties comparable to diamond. It has excellent thermal conductivity, low thermal expansion, and is resistant to acid corrosion. Silicon carbide is an excellent ceramic material suitable for applications requiring good corrosion resistance and wear resistance.

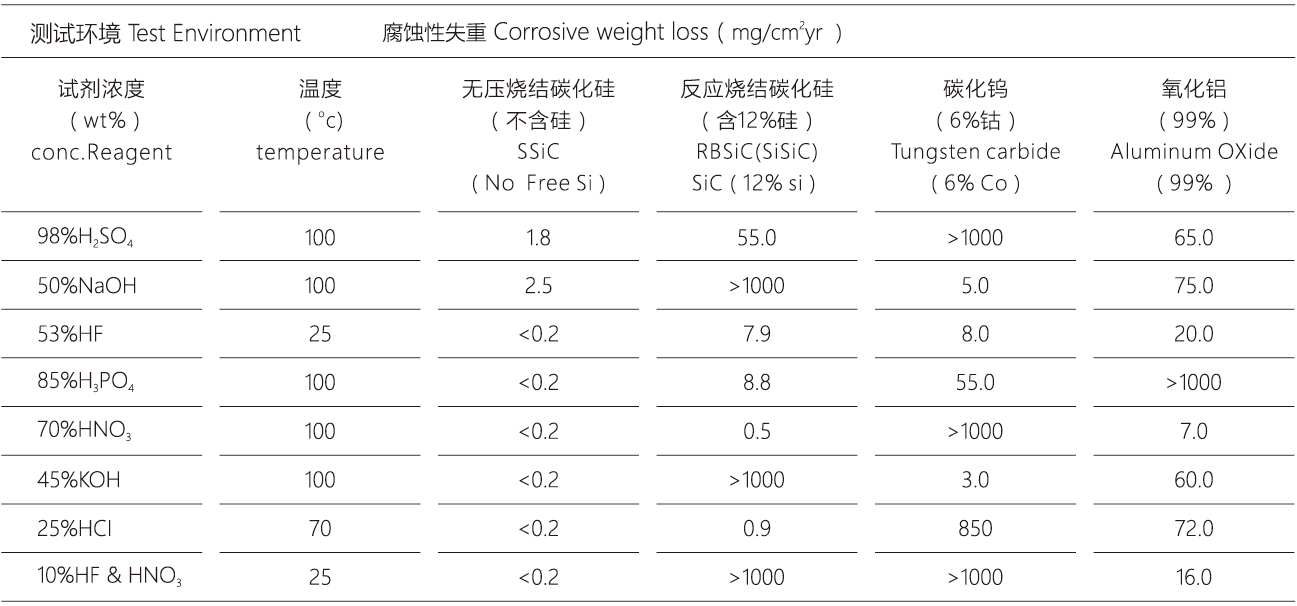

Comparison of parameters of silicon carbide ceramic products of different materials

![]()

Liquid corrosion test data for different materials

Remarks

Our silicon carbide tube and fitting is carefully handled to minimize damage during storage and transportation and to preserve the quality of our products in their original condition. We guarantee intact during transportation, loading and unloading, and have measures to reduce vibration and impact, so as to ensure the integrity of the product during transportation.

Our silicon carbide tube and fitting is carefully handled to minimize damage during storage and transportation and to preserve the quality of our products in their original condition. We guarantee intact during transportation, loading and unloading, and have measures to reduce vibration and impact, so as to ensure the integrity of the product during transportation.

![]()

![]()

Need to inquire about our products? Fill out the form below and our staff will be in touch!

Q: How long is your delivery time?

A: The delivery time of customized products is generally 25 35 days, and non customized products are generally shipped within 24 hours after payment.

Q: Do you provide samples? Is it free?

A: If the value of the sample is low, we will provide it for free, but the freight needs to be paid by the customer. But for some high value samples, we need to charge a fee.

Q: What are your payment terms?

A: T/T 30% as the deposit,The balance payment is paid in full before shipment

Q: What is the packaging and transportation form?

A: Non steaming wooden box and iron frame packaging. Special packaging is available according to customer needs. The transportation is mainly by sea.

Q: What is your minimum order quantity?

A: There is no minimum order quantity requirement. Customized products are tailor made according to the drawings provided by the customer.