Our team is highly trained and experienced in servicing and producing all types of steel supplies. Need help or have a question?

sales@abrasionresistantpipe.com

Tel.: +8621-3378-0199

Our team is highly trained and experienced in servicing and producing all types of steel supplies. Need help or have a question?

sales@abrasionresistantpipe.com

Tel.: +8621-3378-0199

A335/SA335 Grade P22 Alloy Steel Seamless Pipes are Carbon steel pipes with addition of chromium, molybdenum, and sometimes vanadium. Chromium, or chrome, improves high-temperature strength, increases oxidation resistance and raises the tensile, yield and hardness at room temperatures.

A335/SA335 Grade P22 Alloy Steel Seamless Pipes are Carbon steel pipes with addition of chromium, molybdenum, and sometimes vanadium. Chromium, or chrome, improves high-temperature strength, increases oxidation resistance and raises the tensile, yield and hardness at room temperatures. Molybdenum increases the strength, elastic limit, resistance to wear, impact qualities and hardenability. It increases the resistance to softening, restrains grain growth and makes chromium steel less susceptible to embrittlement. Moly is also the most effective additive for increasing high temperature creep strength, or creep resistance, and it also enhances the corrosion resistance of steel and inhibits pitting. Grade P22 is used for high temperature service applications and is tolerant to variations in its microstructure.

Each length of pipe shall be subjected to the hydrostatic test. Also, each pipe shall be examined by a non-destructive examination method in accordance to the required practices.

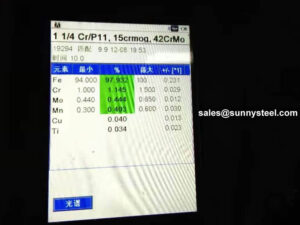

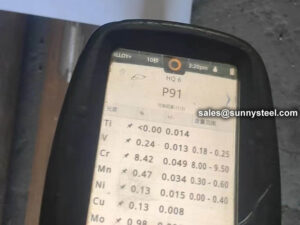

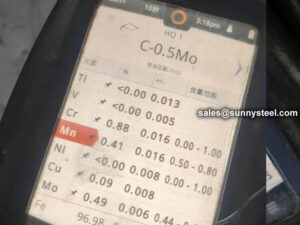

Chemical Composition Inspection, Mechanical Properties Test(Tensile Strength,Yield Strength, Elongation, Flaring, Flattening, Bending, Hardness, Impact Test), Surface and Dimension Test,No-destructive Test, Hydrostatic Test.

Surface treatment:

Oil-dip, Varnish, Passivation, Phosphating, Shot Blasting.

Both ends of each crate will indicate the order no., heat no., dimensions, weight and bundles or as requested.

A335 is often called chrome moly pipe because of the chemical makeup of Molybdenum (Mo) and Chromium (Cr). Molybdenum increases the strength of steel as well as the elastic limit, resistance to wear, impact qualities, and hardenability.

The range of ASTM A335 P22 pipe sizes that may be examined by each method shall be subjected to the limitations in the scope of the respective practice.

The different mechanical test requirements for pipes, namely, transverse or longitudinal tension test, flattening test, and hardness or bend test are presented.Both ends of each crate will indicate the order no., heat no., dimensions, weight and bundles or as requested.

Steel grade: ASTM A335 P22

Packing:

Bare packing/bundle packing/crate packing/wooden protection at the both sides of tubes and suitably protected for sea-worthly delivery or as requested.

| Grade | UN | C≤ | Mn | P≤ | S≤ | Si≤ | Cr | Mo |

|---|---|---|---|---|---|---|---|---|

| P1 | K11522 | 0.10~0.20 | 0.30~0.80 | 0.025 | 0.025 | 0.10~0.50 | – | 0.44~0.65 |

| P2 | K11547 | 0.10~0.20 | 0.30~0.61 | 0.025 | 0.025 | 0.10~0.30 | 0.50~0.81 | 0.44~0.65 |

| P5 | K41545 | 0.15 | 0.30~0.60 | 0.025 | 0.025 | 0.5 | 4.00~6.00 | 0.44~0.65 |

| P5b | K51545 | 0.15 | 0.30~0.60 | 0.025 | 0.025 | 1.00~2.00 | 4.00~6.00 | 0.44~0.65 |

| P5c | K41245 | 0.12 | 0.30~0.60 | 0.025 | 0.025 | 0.5 | 4.00~6.00 | 0.44~0.65 |

| P9 | S50400 | 0.15 | 0.30~0.60 | 0.025 | 0.025 | 0.50~1.00 | 8.00~10.00 | 0.44~0.65 |

| P11 | K11597 | 0.05~0.15 | 0.30~0.61 | 0.025 | 0.025 | 0.50~1.00 | 1.00~1.50 | 0.44~0.65 |

| P12 | K11562 | 0.05~0.15 | 0.30~0.60 | 0.025 | 0.025 | 0.5 | 0.80~1.25 | 0.44~0.65 |

| P15 | K11578 | 0.05~0.15 | 0.30~0.60 | 0.025 | 0.025 | 1.15~1.65 | – | 0.44~0.65 |

| P21 | K31545 | 0.05~0.15 | 0.30~0.60 | 0.025 | 0.025 | 0.5 | 2.65~3.35 | 0.80~1.60 |

| P22 | K21590 | 0.05~0.15 | 0.30~0.60 | 0.025 | 0.025 | 0.5 | 1.90~2.60 | 0.87~1.13 |

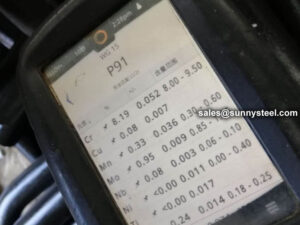

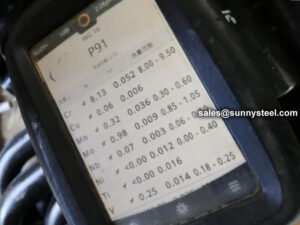

| P91 | K91560 | 0.08~0.12 | 0.30~0.60 | 0.02 | 0.01 | 0.20~0.50 | 8.00~9.50 | 0.85~1.05 |

| P92 | K92460 | 0.07~0.13 | 0.30~0.60 | 0.02 | 0.01 | 0.5 | 8.50~9.50 | 0.30~0.60 |

| Werkstoff /DIN | EN | ASTM |

|---|---|---|

| 1.5415 | 16Mo3 | A335 Grade P1 |

| 1.7335 | 13CrMo4-5 | A335 Grade P11, P12 |

| 1.738 | 10CrMo9-10 | A335 Grade P22 |

| 1.7362 | X11CrMo5 | A335 Grade P5 |

| A335 Grade P9 | ||

| 1.4903 | X10CrMoVNb9-1 | A335 Grade P91 |

| Tensile Strength, min., psi | P-5 | P-9 | P-11 | P-22 | P-91 |

|---|---|---|---|---|---|

| ksi | 60 | 60 | 60 | 60 | 85 |

| MPa | 415 | 415 | 415 | 415 | 585 |

| Yield Strength, min., psi | |||||

| ksi | 30 | 30 | 30 | 30 | 60 |

| MPa | 205 | 205 | 205 | 205 | 415 |

| Grade | Tensile strength | Yield strength |

|---|---|---|

| P1,P2 | 380 | 205 |

| P12 | 415 | 220 |

| P23 | 510 | 400 |

| P91 | 585 | 415 |

| P92,P11 | 620 | 440 |

| P122 | 620 | 400 |

| Grade | Heat Treatment Type P5, P9, P11, and P22 | Normalizing Temperature Range F [C] | Subcritical Annealing or Tempering Temperature Range F [C] |

|---|---|---|---|

| A335 P5 (b,c) | Full or Isothermal Anneal | ||

| Normalize and Temper | ***** | 1250 [675] | |

| Subcritical Anneal (P5c only) | ***** | 1325 – 1375 [715 - 745] | |

| A335 P9 | Full or Isothermal Anneal | ||

| Normalize and Temper | ***** | 1250 [675] | |

| A335 P11 | Full or Isothermal Anneal | ||

| Normalize and Temper | ***** | 1200 [650] | |

| A335 P22 | Full or Isothermal Anneal | ||

| Normalize and Temper | ***** | 1250 [675] | |

| A335 P91 | Normalize and Temper | 1900-1975 [1040 - 1080] | 1350-1470 [730 - 800] |

| Quench and Temper | 1900-1975 [1040 - 1080] | 1350-1470 [730 - 800] |

Material & Manufacture

Pipe may be either hot finished or cold drawn with the finishing heat treatment noted below.

Heat Treatment

Mechanical Tests Specified

Notes for Hardness Test:

Notes for Bend Test:

Cold Drawn Seamless Mechanical Tubing (CDS) is a cold drawn 1018/1026 steel tube which offers uniform tolerances, enhanced machinability and increased strength and tolerances compared to hot-rolled products.

Cold drawn steel tube is with hot-rolled steel coil as raw material, and tandem cold rolling pickled to remove oxide scale, its finished rolling hard roll, rolling hard volumes due to the continuous cold deformation caused by cold hardening strength, hardness increased indicators declined tough plastic, stamping performance will deteriorate, which can only be used for simple deformation of the parts.

Rolling hard roll can be used as the raw material of the hot-dip galvanizing plant, hot dip galvanizing line set annealing line. Rolling hard roll weight is generally 6 to 13.5 tons, the coil diameter of 610mm.

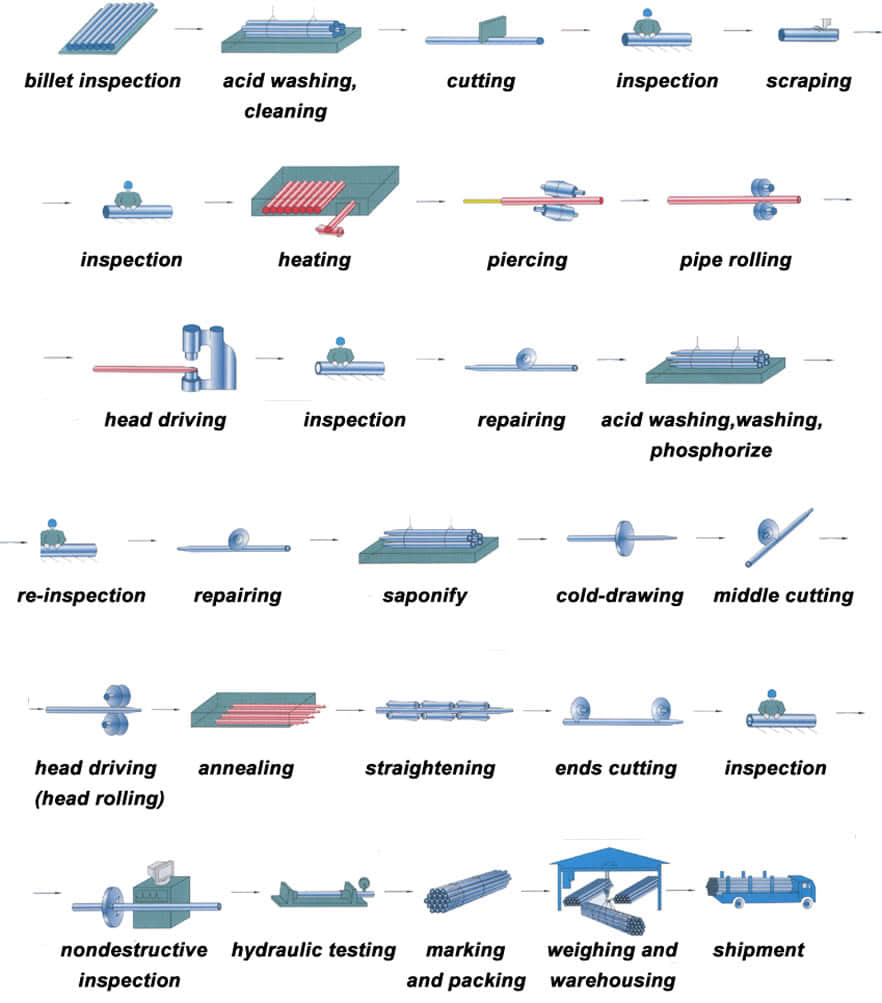

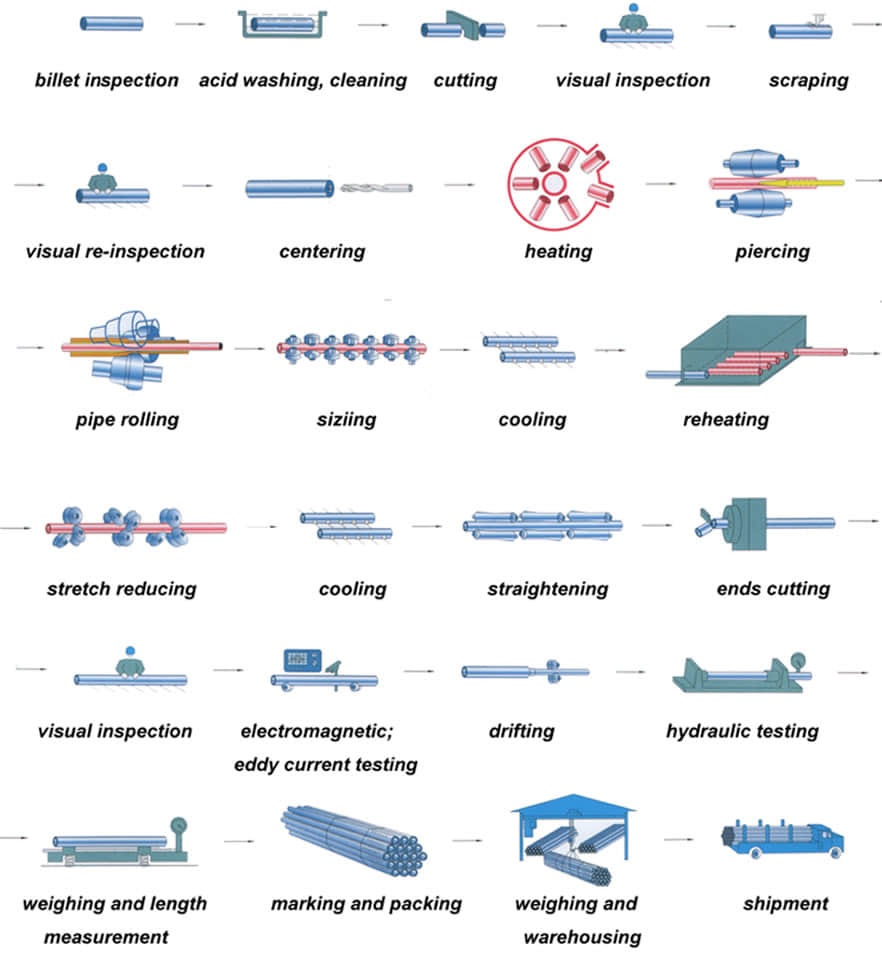

Hot-rolled seamless steel pipe production base deformation process can be summarized as three stages: perforation, extension and finishing.

The main purpose of the perforation process is to become a solid round billet piercing hollow shell. Capillary in the specifications, accuracy and surface quality can not meet the requirements of the finished product, further improvements are needed to deform the metal through. The main purpose of the stretching machine is further reduced sectional view (main compression wall) for a larger axial extension, so that the capillary improved dimensional accuracy, surface quality and organizational performance.

After stretching machine rolled steel pipe shortage collectively need further molding mill in order to achieve the requirements of the finished pipe. Rolled steel due to pass in the method widely used in the production of seamless steel tubes.

So far, due to the method pass rolling steel can be divided into two categories: core pension without rolling rolling (hollow body rolling), and with the mandrel. Sizing machines, reducing mill and stretch reducing mill belonging to the hole without mandrel type continuous rolling mills are generally coffin. Its main purpose is to reduce the diameter of the deformation process or sizing get finished steel, the wall thickness of process control, can make thinning, thickening or nearly unchanged.

All the traditional hole-type rolling machine with mandrel belong to extend machine. The main purpose is to reduce the deformation process perforated capillary wall thickness and outer diameter roll passes in the deformation zone and the mandrel posed, for a larger axial extension. At the same time a certain improvement in the organization, performance, accuracy, surface quality.

Before cutting pipe and tubing

No matter the material, measure the diameter of the pipe or tube to be cut to ensure that you use the right-size tube cutter for the job. When determining how to make a straight cut, use a tape measure and a pencil or other writing instrument to mark on the surface where you want to cut. If possible, mark around the circumference of a pipe, especially when cutting with a handsaw. Ensure that a cut is as straight as possible by securing the pipe with a vise, clamp, miter box or even duct tape to keep the length from shifting out of place while cutting.

After cutting pipe and tubing

Inspection and test of alloy steel pipe:

Chemical composition inspection, mechanical properties test(tensile strength,yield strength, elongation, flaring, flattening, bending, hardness, impact test), surface and dimension test,no-destructive test, hydrostatic test.

Bare packing/bundle packing/crate packing/wooden protection at the both sides of tubes and suitably protected for sea-worthly delivery or as requested.

Alloy steel pipes are ideally suitable for chemical, petrochemicals, and other energy-related applications.

Alloy steel pipes are ideally suitable for chemical, petrochemicals, and other energy-related applications.

The alloy steel pipe adopts high quality carbon steel, alloy structural steel and stainless & heat resisting steel as raw material through hot rolling or cold drawn to be made.

Alloy steel can be used in process area where carbon steel has limitation such as

As an important element of steel products, alloy steel pipe can be divided into seamless steel pipe and welded steel pipe according to the manufacturing technique and tube billet shape.

Here you can see the common alloy steel grade that you will come across.

Why the application of alloy steel pipe is wider than others

There are many kinds of materials used for transport in industrial production. Specifically we will have more choices and it is not limited to the use of alloy steel pipe. But even in the face of more choices, many people tend to choose alloy steel pipe. People make their own choices will have their own reasons. This means the alloy steel pipe application has its own advantages. Compared with transmission lines made of other materials, after it meets the basic application requirements, its quantity is lighter. Then in the practical application of alloy steel pipe, it will have more advantages because of this. Besides its physical characteristic advantage, it also has economic advantages. The wide application of alloy steel pipe is with kinds of reasons. So in practical usage, we can exploit the advantages to the full, in this way can we get more profits in these applications of alloy steel pipe.

What requirements should alloy steel pipe application meet

The transportation of kinds of gases or liquids in production needs to rely on alloy steel pipe. This shows that the actual role of alloy steel pipe application is important. High temperature resistant and low temperature resistant is the tolerance of temperature. In the practical application of alloy steel pipe, there will be many materials need to be transported. However their temperatures are not the same. So this can be the basic requirement to alloy steel pipe. It needs more corrosion resistance. Corrosion resistant material is the best material during transporting, because it is corrosion resistant. So it can be used in more occasions. And it is definitely very convenient for users.

The biggest advantages of alloy steel pipe

Can be 100% recycled, environmentally friendly, energy-saving, resource conservation, national strategy, national policy to encourage the expansion of the field of application of high-pressure alloy pipe. Of alloy steel pipe total consumption accounted steel in the proportion is only half of the developed countries, to expand the field of use of the alloy steel pipe to provide a wider space for the development of the industry. The future needs of the average annual growth of China’s high-pressure alloy steel pipe long products up to 10-12%.

Specification, standard and identification of alloy steel pipes

Alloy Steel pipe contains substantial quantities of elements other than carbon such as nickel, chromium, silicon, manganese, tungsten, molybdenum, vanadium and limited amounts of other commonly accepted elements such as manganese, sulfur, silicon, and phosphorous.

Our team of experienced sales specialists proudly partners with gas and chemical processors, power generation plants, oil refineries, and related industries to offer piping components and value-added services.

The biggest advantages of alloy steel pipe can be 100% recycled, environmentally friendly, energy-saving, resource conservation, national strategy, national policy to encourage the expansion of the field of application of high-pressure alloy pipe. Of alloy tube total consumption accounted steel in the proportion is only half of the developed countries, to expand the field of use of the alloy tube to provide a wider space for the development of the industry. According to the Chinese Special Steel Association alloy pipe Branch Expert Group, the future needs of the average annual growth of China’s high-pressure alloy pipe long products up to 10-12%.

Our team of experienced sales specialists proudly partners with gas and chemical processors, power generation plants, oil refineries, and related industries to offer piping components and value-added services.

| Alloying Elements | Effect on the Properties |

|---|---|

| Chromium | Increases Resistance to corrosion and oxidation. Increases hardenability and wear resistance. Increases high temperature strength. |

| Nickel | Increases hardenability. Improves toughness. Increases impact strength at low temperatures. |

| Molybdenum | Increases hardenability, high temperature hardness, and wear resistance. Enhances the effects of other alloying elements. Eliminate temper brittleness in steels. Increases high temperature strength. |

| Manganese | Increases hardenability. Combines with sulfur to reduce its adverse effects. |

| Vanadium | Increases hardenability, high temperature hardness, and wear resistance. Improves fatigue resistance. |

| Titanium | Strongest carbide former. Added to stainless steel to prevent precipitation of chromium carbide. |

| Silicon | Removes oxygen in steel making. Improves toughness. Increases hardness ability |

| Boron | Increases hardenability. Produces fine grain size. |

| Aluminum | Forms nitride in nitriding steels. Produces fine grain size in casting. Removes oxygen in steel melting. |

| Cobalt | Increases heat and wear resistance. |

| Tungsten | Increases hardness at elevated temperatures. Refines grain size. |

Alloy steels are made by combining carbon steel with one or several alloying elements, such as manganese, silicon, nickel, titanium, copper, chromium and aluminum. These metals are added to produce specific properties that are not found in regular carbon steel. The elements are added in varying proportions (or combinations) making the material take on different aspects such as increased hardness, increased corrosion resistance, increased strength, improved formability (ductility); the weldability can also change.

Norms:

Grade:

Need to inquire about our products? Fill out the form below and our staff will be in touch!

Q: How long is your delivery time?

A: The delivery time of customized products is generally 25 35 days, and non customized products are generally shipped within 24 hours after payment.

Q: Do you provide samples? Is it free?

A: If the value of the sample is low, we will provide it for free, but the freight needs to be paid by the customer. But for some high value samples, we need to charge a fee.

Q: What are your payment terms?

A: T/T 30% as the deposit,The balance payment is paid in full before shipment

Q: What is the packaging and transportation form?

A: Non steaming wooden box and iron frame packaging. Special packaging is available according to customer needs. The transportation is mainly by sea.

Q: What is your minimum order quantity?

A: There is no minimum order quantity requirement. Customized products are tailor made according to the drawings provided by the customer.