Our team is highly trained and experienced in servicing and producing all types of steel supplies. Need help or have a question?

sales@abrasionresistantpipe.com

Tel.: +8621-3378-0199

Our team is highly trained and experienced in servicing and producing all types of steel supplies. Need help or have a question?

sales@abrasionresistantpipe.com

Tel.: +8621-3378-0199

Mechanical steel tubes are used in machined or formed parts of industrial, automotive, farm machinery, aircraft, transportation, materials handling, and household equipment. It is produced to exact outside diameter and wall thickness dimensions.

Mechanical steel tubes are used in machined or formed parts of industrial, automotive, farm machinery, aircraft, transportation, materials handling, and household equipment. It is produced to exact outside diameter and wall thickness dimensions.

Mechanical tubes are used for mechanical and light gauge structural applications.

Mechanical tubes are produced to meet specific end use requirements, specifications, tolerances and chemistries.

Tubing used for mechanical and light gauge structural applications. This allows for more specific property uniformity throughout the tube compared to standard pipe or tube. While Mechanical tube can be produced to standard specifications when requested, it is often produced to “typical” properties that focus mainly on the yield strength for a precise size and wall thickness. In some applications with severe forming, yield strength may not even be specified and the mechanical tube is produced to be “fit for use”. Mechanical tubing encompasses a wide range of both structural and non-structural applications.

At SunnySteel, we apply our metallurgical and production expertise to manufacture high-performance seamless mechanical tube products to meet your needs.

This includes carbon, alloy and even custom steel grades; annealed, normalized and tempered; stress relieved and stress free; and quench and tempered.

Seamless Steel Tubes for Mechanical and Automobile usage for Backbone of Automobile and rear axle tube, manufacturing and processing of precision equipments, instruments and apparatus.

Sunny Steel supply a 1/2 million foot inventory of carbon steel pressure tubing including boiler tubes, condenser tubes and heat exchanger tubes all made in the China.

Our carbon steel pressure tubing inventory is manufactured in accordance with ASME SA-178 A and/or ASME SA-214 in diameters of 3/4″ through 4”.

Application:

Backbone of Automobile and rear axle tube

Manufacturing and processing of precision equipments, instruments and apparatus

Delivery Condition: GBK, BKS, BK, BKW, NBK

Inspection and Test:

Chemical Composition, Mechanical Properties, Visual and Dimension Test, NDT, Grain Size Test

Surface treatment:

Oil-dip, Varnish, Shot Blasting

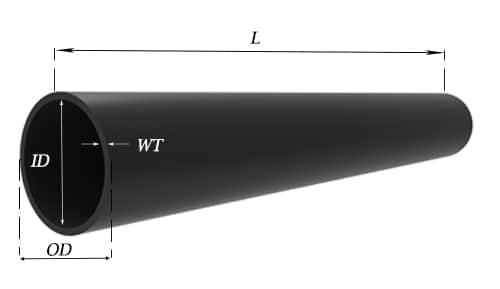

Size Range

Tubular products seamless mechanical tubing is furnished in both cold-drawn and hot finished form in a wide range of sizes, from 1.375″ to 7.750″ OD and from 0.188″ to 1.625″ wall thickness.

Minimum Quantities

Special Configurations

Tubular Products special seamless tubing configurations start with the highest quality steels. Grade, chemical analysis and surface condition are carefully considered, and production processes are tailored to achieve the best tubing for the end use.

The configurations are formed from round tube by cold drawing. The tube is drawn over a shaped mandrel or through a shaped die, or both. Improved tolerances, finishes and mechanical properties result.

Seamless and welded tubes for mechanical and general engineering applications. Tubes for construction and structural purposes such as civil structures, foundations, etc.

| Abbr. | Corresponding | Application |

|---|---|---|

| A511 | ASTM A511 / A511M | Specification for Seamless Stainless Steel Mechanical Tubing |

| A512 | ASTM A512 / ASME SA512 | Specification for Cold-Drawn Buttweld Carbon Steel Mechanical Tubing |

| A513 | ASTM A513 / A513M | Specification for Electric-Resistance-Welded Carbon and Alloy Steel Mechanical Tubing |

| A519 | ASTM A519 / A519M | Specification for Seamless Carbon and Alloy Steel Mechanical Tubing |

| A554 | ASTM A554 | Specification for Welded Stainless Steel Mechanical Tubing |

In the world of tubing, things can get a bit confusing. With many different types of tubing for different applications, terms and meanings can be a bit ambiguous. With this in mind, we’ve set out to explain the difference between structural tubing and mechanical tubing.

Mechanical Tubing:

tubing used for mechanical and light gauge structural applications. Mechanical tube is produced to meet specific end use requirements, specifications, tolerances and chemistries. This allows for more specific property uniformity throughout the tube compared to standard pipe. While Mechanical tube can be produced to standard specifications when requested, it is often produced to “typical” properties that focus mainly on the yield strength for a particular size and wall thickness. In some applications with severe forming, yield strength may not even be specified and the Mechanical tube is produced to be “fit for use”.

Structural Tubing:

tubing used for structural applications. Standard strength requirements of the tube help dictate applications for which certain tubing is most appropriate. Structural tube is often referred to as hollow structural sections or HSS.

Mechanical tubing encompasses a wide range of both structural and non-structural applications.

Mechanical Tube

Structural Tube

Mechanical Tube

Structural Tube

Mechanical Tube

At Wheatland Tube, our mechanical tubing is manufactured to typical Mechanical tube properties or in accordance with ASTM A500 and A513 Types 1 and 2 specifications.

Our Mechanical tubing is not limited to these specifications and can be produced to specific customer requirements when appropriate.

Additionally, our in-line galvanized products comply with A1057 and A787 coating specifications and provide a synergistic triple-coat process for enhanced product life.

Structural Tube

While specifications will vary based on design (and from manufacturer to manufacturer), some common specifications of structural tubing include ASTM A500 Grade B and C, A847, A1065, and the recently approved ASTM A1085.

In both cases of “Structural” or “Mechanical” tubing, these products are ordered to a specific outside dimension (OD) and “gauge” or wall thickness. This varies from “pipe” products which are ordered based on inside dimensions (ID) and often pipe “schedules” that determine the wall thickness. Pipe and conduit products should not be used in structural applications as their strength properties may not be produced to standard structural specifications or meet specified engineering requirements.

| Abbr. | Corresponding | Application |

|---|---|---|

| A511 | ASTM A511 / A511M | Specification for Seamless Stainless Steel Mechanical Tubing |

| A512 | ASTM A512 / ASME SA512 | Specification for Cold-Drawn Buttweld Carbon Steel Mechanical Tubing |

| A513 | ASTM A513 / A513M | Specification for Electric-Resistance-Welded Carbon and Alloy Steel Mechanical Tubing |

| A519 | ASTM A519 / A519M | Specification for Seamless Carbon and Alloy Steel Mechanical Tubing |

| A554 | ASTM A554 | Specification for Welded Stainless Steel Mechanical Tubing |

The production of our seamless pipes is tightly regulated and all of the pipes we stock have been fully tested to international standards to ensure we only supply the highest quality products.

| Product name | Executive standard | Dimension (mm) | Steel code/ Steel grade |

|---|---|---|---|

| Black and Hot-dipped Zinc-coated Steel Pipes Seamless | ASTM A53 | 0.3-1200 x 1.0-150 | GR.A, GR.B, GR.C |

| Seamless Carbon Steel for High Temperature Service | ASTM A106 | 10.3-1200 x 1.0-150 | GR.B, GR.C |

| Seamless Cold-drawn Low-Carbon Steel Heat-Exchanger and Condenser Tubes | ASTM A179 | 10.3-426 x 1.0-36 | Low Carbon Steel |

| Seamless Carbon Steel Boiler Tubes for High Pressure | ASTM A192 | 10.3-426 x 1.0-36 | Low Carbon Steel |

| Seamless Cold-drawn Intermediate Alloy Steel Heat-exchanger and Condenser Tubes | ASTM A199 | 10.3-426 x 1.0-36 | T5, T22 |

| Seamless Medium-carbon Steel Boiler and Superheater Tubes | ASTM A210 | 10.3-426 x 1.0-36 | A1, C |

| Seamless Ferritic and Austenitic Alloy Steel Boiler, Superheater and Heat-exchanger Tubes | ASTM A213 | 10.3-426 x 1.0-36 | T5, T5b, T9 , T11, T22 ,T91 |

| Seamless Carbon and Alloy Steel for Mechanical Tubing | ASTM A333 | 1/4"-42" x SCH20-XXS | Grade1 Gr. 3,Gr..6, Gr.8 , Gr. 9 |

| Seamless Cold-drawn Carbon Steel Feedwater Heater Tubes | ASTM A556 | 10.3-426 x 1.0-36 | A2, B2 |

| Round and shaped steel cold formed welded and seamless carbon steel structural pipe. | ASTM A500 | OD :10.3-820 x 0.8- 75 | Grade A, B, C, D |

| Carbon and alloy steel mechanical tubing, either hot-finished or cold-finished | ASTM A519 | 10.3-426 x 1.0-36 | 1020, 1025, 4130, 4140 |

| For seamless ferritic alloy-steel pipe for high-temperature service | ASTM A335 | 1/4"-42" x SCH20-XXS | A/SA 335 P1, P2, P11, P12, P15, P22, P91, P92, P122 |

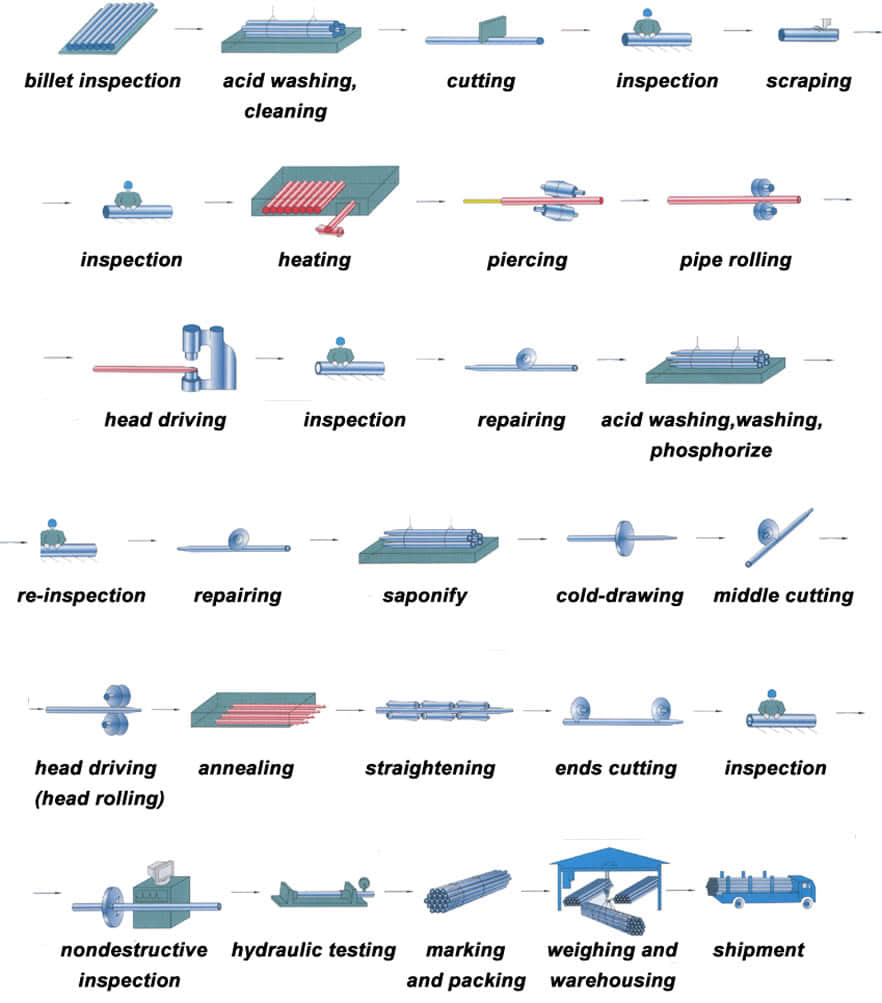

Cold Drawn Seamless Mechanical Tubing (CDS) is a cold drawn 1018/1026 steel tube which offers uniform tolerances, enhanced machinability and increased strength and tolerances compared to hot-rolled products.  Cold drawn steel tube is with hot-rolled steel coil as raw material, and tandem cold rolling pickled to remove oxide scale, its finished rolling hard roll, rolling hard volumes due to the continuous cold deformation caused by cold hardening strength, hardness increased indicators declined tough plastic, stamping performance will deteriorate, which can only be used for simple deformation of the parts. Rolling hard roll can be used as the raw material of the hot-dip galvanizing plant, hot dip galvanizing line set annealing line. Rolling hard roll weight is generally 6 to 13.5 tons, the coil diameter of 610mm.

Cold drawn steel tube is with hot-rolled steel coil as raw material, and tandem cold rolling pickled to remove oxide scale, its finished rolling hard roll, rolling hard volumes due to the continuous cold deformation caused by cold hardening strength, hardness increased indicators declined tough plastic, stamping performance will deteriorate, which can only be used for simple deformation of the parts. Rolling hard roll can be used as the raw material of the hot-dip galvanizing plant, hot dip galvanizing line set annealing line. Rolling hard roll weight is generally 6 to 13.5 tons, the coil diameter of 610mm.

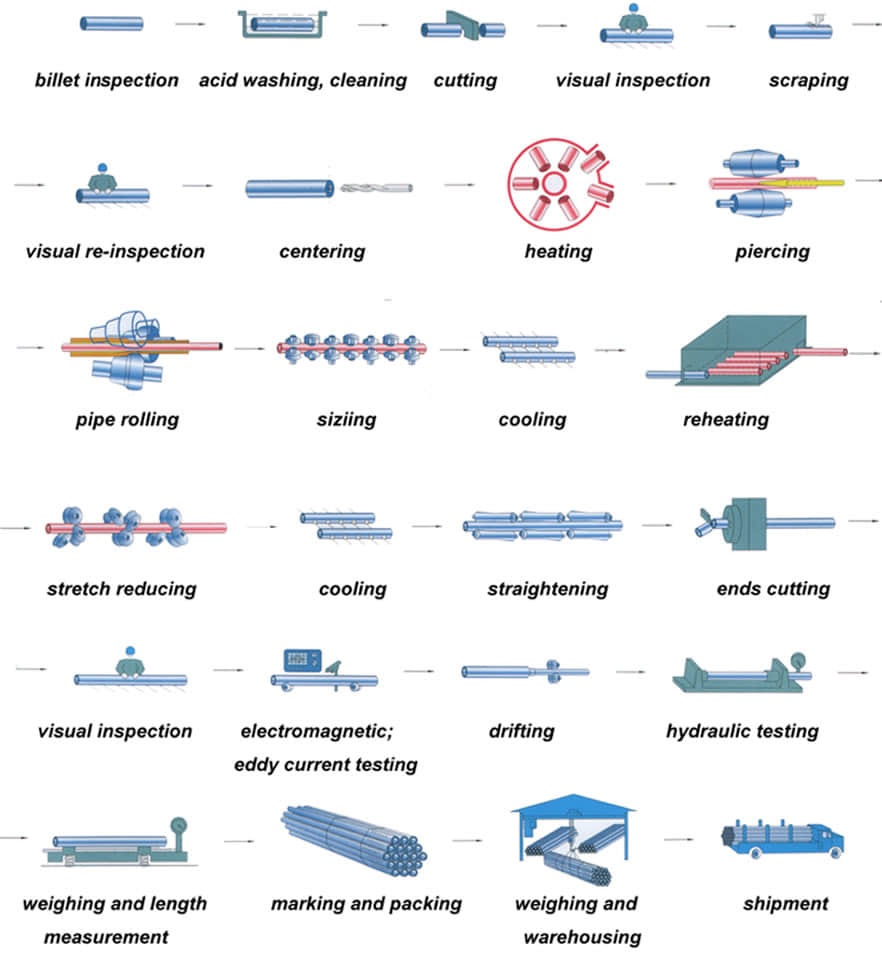

Hot-rolled seamless steel pipe production base deformation process can be summarized as three stages: perforation, extension and finishing.  The main purpose of the perforation process is to become a solid round billet piercing hollow shell. Capillary in the specifications, accuracy and surface quality can not meet the requirements of the finished product, further improvements are needed to deform the metal through. The main purpose of the stretching machine is further reduced sectional view (main compression wall) for a larger axial extension, so that the capillary improved dimensional accuracy, surface quality and organizational performance. After stretching machine rolled steel pipe shortage collectively need further molding mill in order to achieve the requirements of the finished pipe. Rolled steel due to pass in the method widely used in the production of seamless steel tubes. So far, due to the method pass rolling steel can be divided into two categories: core pension without rolling rolling (hollow body rolling), and with the mandrel. Sizing machines, reducing mill and stretch reducing mill belonging to the hole without mandrel type continuous rolling mills are generally coffin. Its main purpose is to reduce the diameter of the deformation process or sizing get finished steel, the wall thickness of process control, can make thinning, thickening or nearly unchanged. All the traditional hole-type rolling machine with mandrel belong to extend machine. The main purpose is to reduce the deformation process perforated capillary wall thickness and outer diameter roll passes in the deformation zone and the mandrel posed, for a larger axial extension. At the same time a certain improvement in the organization, performance, accuracy, surface quality.

The main purpose of the perforation process is to become a solid round billet piercing hollow shell. Capillary in the specifications, accuracy and surface quality can not meet the requirements of the finished product, further improvements are needed to deform the metal through. The main purpose of the stretching machine is further reduced sectional view (main compression wall) for a larger axial extension, so that the capillary improved dimensional accuracy, surface quality and organizational performance. After stretching machine rolled steel pipe shortage collectively need further molding mill in order to achieve the requirements of the finished pipe. Rolled steel due to pass in the method widely used in the production of seamless steel tubes. So far, due to the method pass rolling steel can be divided into two categories: core pension without rolling rolling (hollow body rolling), and with the mandrel. Sizing machines, reducing mill and stretch reducing mill belonging to the hole without mandrel type continuous rolling mills are generally coffin. Its main purpose is to reduce the diameter of the deformation process or sizing get finished steel, the wall thickness of process control, can make thinning, thickening or nearly unchanged. All the traditional hole-type rolling machine with mandrel belong to extend machine. The main purpose is to reduce the deformation process perforated capillary wall thickness and outer diameter roll passes in the deformation zone and the mandrel posed, for a larger axial extension. At the same time a certain improvement in the organization, performance, accuracy, surface quality.

Before cutting pipe and tubing No matter the material, measure the diameter of the pipe or tube to be cut to ensure that you use the right-size tube cutter for the job. When determining how to make a straight cut, use a tape measure and a pencil or other writing instrument to mark on the surface where you want to cut. If possible, mark around the circumference of a pipe, especially when cutting with a handsaw. Ensure that a cut is as straight as possible by securing the pipe with a vise, clamp, miter box or even duct tape to keep the length from shifting out of place while cutting. After cutting pipe and tubing

Geometrical inspection of steel pipes The outer diameter, wall thickness, bending and length of the steel pipe can be inspected on the inspection table with an outer caliper, a micrometer and a bending ruler, and a length tape measure.

Take seamless steel pipe as an example, there are some tolerances that affect quality. Noting this, and you will get a better pipe.

Weight tolerance

For pipe NPS 12 (DN300, 323.8mm) and under, the weight shall vary within -3.5% / +10%.

For pipe over NPS 12 (DN300, 323.8mm), the weight shall vary within -5% / +10%.

Pipe of NPS 4 (DN100, 114.3mm) and smaller may be weighed in convenient lots; pipe in sizes larger than NPS 4 shall be weighed separately.

Quantity tolerance

Normally mills take -10% to +10% tolerance, but TPMCSTEEL keeps ±3% variation.

Length tolerance

For Seamless pipe& tube, if definite cut lengths are ordered, the length shall vary within -0mm / +6mm.

| Pipe types | Pipe Szie(mm) | Tolerances | |

|---|---|---|---|

| Hot rolled | OD | <50 | ±0.50mm |

| ≥50 | ±1% | ||

| WT | <4 | ±12.5% | |

| ≥4-20 | +15%, -12.5% | ||

| >20 | ±12.5% | ||

| Cold drawn | OD | 6-10 | ±0.20mm |

| 10-30 | ±0.40mm | ||

| 30-50 | ±0.45 | ||

| >50 | ±1% | ||

| WT | <1 | ±0.15mm | |

| >1-3 | + 15%, – 10% | ||

| >3 | + 12.5%, – 10% | ||

| Standard | Hot finished seamless tube | Cold flnished seamless tube | ||

|---|---|---|---|---|

| Out diameter (mm) | Tolerance | Out diameter (mm) | Tolerance | |

| EN10216-1 | ≤100 | +/-0.75% (min.+/-0.5mm) | All | +/-0.5% |

| EN10216-2 | (min. +/-0.30mm) | |||

| DIN17175 | >100 | +/-0.90% | ||

| GB/T 3087 | ≤460 | +/-0.75% (min.+/-0.5mm) | 10-30 | +/-0.40mm |

| >30-50 | +/-0.45mm | |||

| >50 | +/-1.0% | |||

| GB/T 5310 GB/T 9948 GB/T 6479 | <57 | +/-0.40mm | ≤30 | +/-0.20mm |

| 57-325 | +/-0.75% | >30-50 | +/-0.30mm | |

| >325-460 | +1%,-2mm | >50 | +/-0.8% | |

| ASME SA-179M ASME SA-192M ASME SA-209M ASME SA-210M ASME SA-213M JIS G 3461 JIS G 3461 | ≤101.6 | +0.4, -0.8mm | <25.4 | +/-0.10mm |

| >25.4-38.1 | +/-0.15mm | |||

| >38.1-50.8 | +/-0.20mm | |||

| 101.6-190.5 | +0.4, -1.2mm | >50.8-63.5 | +/-0.25mm | |

| >63.5-76.2 | +/-0.30mm | |||

| >76.2 | +/-0.38mm | |||

| ASME SA106 ASME SA335 | ≤48.3 | +/-0.40mm | ≤48.3 | +/-0.40mm |

| 48.3-114.3 | +/-0.79mm | |||

| 114.4-219.1 | +1.59, -0.79mm | |||

| 219.2-323.9 | +2.38, -0.79mm | >48.3 | +/-0.79mm | |

| >324 | +/-1.0% | |||

| Standard | Hot finished seamless tube | Cold flnished seamless tube | ||||

|---|---|---|---|---|---|---|

| DIN17175 | Out diameter OD(mm) | Wall thickness T(mm) | Tolerance | Out diameter (mm) | Wall Thickness T(mm) | Tolerance |

| ≤130 | S≤2Sn | +15%, -10% | -- | All | +/-10% (min. +/-0.2mm) |

|

2Sn| +12.5%, -10% |

| |||||

| S>4Sn | +-/9% | |||||

| >130 | S≤0.05da | +17.5%, -12.5% | ||||

0.05da| +/-12.5% |

| |||||

| S>0.11da | +/-10% | |||||

| EN 10216-1 EN 10216-2 | ≤219.1 | - | +/-12.5% (min.+/-0.4mm) |

|||

| -- | T/D≤0.025 | +/-20% | ||||

0.025| +/-15% |

| |||||

0.05| +/-12.5% |

| |||||

0.1| +/-10% |

| |||||

| GB/T 3087 | -- | ≤20 | +15%,-12.5% (min.+0.45, -0.35mm) | -- | 1.0-3.0 | +15%, -10% |

| >20 | +/-12.5% | -- | >3 | +12.5%, -10% | ||

| GB/T 5310 GB/T 9948 GB/T 6479 | -- | <4.0 | +15%,-10% (min.+0.48, -0.32mm) | -- | 2-3 | +12%,-10% |

| 4-20 | +12.5%,-10% | >3 | +/-10% | |||

| >20 | +/-10% | |||||

| ASME SA-179M ASME SA-192M ASME SA-209M ASME SA-210M ASME SA-231M JIS G 3461 JIS G 3462 | -- | 2.41-3.8 | +35%, -0% | ≤38.1 | -- | +20%,-0% |

| 3.8-4.6 | +33%,-0% | >38.1 | -- | 22%,-0% | ||

| >4.6 | +28%,-0% | -- | -- | -- | ||

| ASME SA-106 ASME SA-335 | -- | All | +/12.5% | All | +/-10% | |

Note:

Positive material identification (PMI) testing is the examination of a material, usually a metallic alloy, to confirm the material is consistent with the user’s request.

Steel pipe delivery status(condition): cold / hard (BK), cold / soft (BKW), after cold stress relief annealing (BKS), annealing (GBK), normalized (NBK).

| Term | Symbol | Explanation |

|---|---|---|

| Cold-finished/hard (cold-finished as-drawn) | BK | No heat treatment after the last cold-forming process. The tubes therefore have only low deformability. |

| Cold-finished/soft (lightly cold-worked) | BKW | After the last heat treatment there is a light finishing pass (cold drawing) With proper subsequent processing, the tube can be cold-formed (e.g. bent, expanded) within certain limits. |

| Annealed | GBK | After the final cold-forming process the tubes are annealed in a controlled atmosphere or under vacuum. |

| Normalized | NBK | The tubes are annealed above the upper transformation point in a controlled atmosphere or under vacuum. |

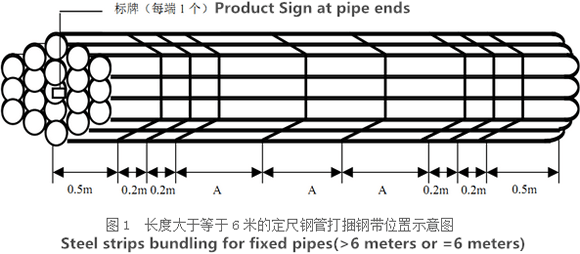

There are probably hundreds of different methods for packing a pipe, and most of them have merit, but there are two principles that are vital for any method to work prevent rusting and Sea transportation security.

Our packing can meet any needs of the customers.

Need to inquire about our products? Fill out the form below and our staff will be in touch!

Q: How long is your delivery time? A: The delivery time of customized products is generally 25 35 days, and non customized products are generally shipped within 24 hours after payment. Q: Do you provide samples? Is it free? A: If the value of the sample is low, we will provide it for free, but the freight needs to be paid by the customer. But for some high value samples, we need to charge a fee. Q: What are your payment terms? A: T/T 30% as the deposit,The balance payment is paid in full before shipment Q: What is the packaging and transportation form? A: Non steaming wooden box and iron frame packaging. Special packaging is available according to customer needs. The transportation is mainly by sea. Q: What is your minimum order quantity? A: There is no minimum order quantity requirement. Customized products are tailor made according to the drawings provided by the customer.