Our team is highly trained and experienced in servicing and producing all types of steel supplies. Need help or have a question?

sales@abrasionresistantpipe.com

Tel.: +8621-3378-0199

Our team is highly trained and experienced in servicing and producing all types of steel supplies. Need help or have a question?

sales@abrasionresistantpipe.com

Tel.: +8621-3378-0199

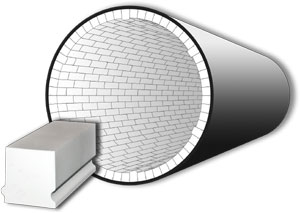

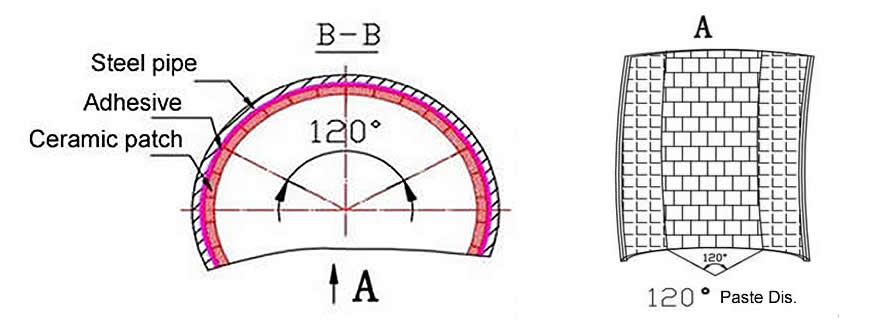

High Alumina ceramic lined conveying wear resistant elbow consist of three parts (steel pipe + adhesive + ceramic tiles), the steel pipe is made of seamless carbon steel pipe. Abrasion resistant ceramic tile lined steel pipes are applicable for the pneumatic powder-feeding, and can be used under a temperature of 350℃without aging and peeling for long life. The service life is 4-5 times than the normal abrasion-resistant pipes.

High Alumina ceramic lined conveying wear resistant elbow consist of three parts (steel pipe + adhesive + ceramic tiles), the steel pipe is made of seamless carbon steel pipe. Abrasion resistant ceramic tile lined steel pipes are applicable for the pneumatic powder-feeding, and can be used under a temperature of 350℃without aging and peeling for long life. The service life is 4-5 times than the normal abrasion-resistant pipes.

Ceramic tile lined pipe is our company to absorb similar products at home and abroad on the basis of advanced technology developed a shell for the steel body, within the wear-resistant ceramic tube of the new composite pipe products, with high wear resistance long service life And so on

Ceramic tile lined pipe is our company to absorb similar products at home and abroad on the basis of advanced technology developed a shell for the steel body, within the wear-resistant ceramic tube of the new composite pipe products, with high wear resistance long service life And so on

The use of anti-off porcelain tube, porcelain tube mosaic, so that paste more flat, more solid with a strong inorganic adhesive paste, wear-resistant steel bowl welding, porcelain and steel body combined to form a double reinforcement to ensure that the porcelain tube does not fall off. The installation of flexible, high wear resistance, processing convenience, the cost is moderate.

High hardness

Rockwell hardness of high alumina ceramics is up to HRA80-90 which is second only to diamond and far exceeds wear-resistant steel stainless

Excellent wear resistance

The wear resistance of high alumina ceramics is 266 times that of manganese steel and 171.5 times that of high chromium cast iron. According to our investigation & follow-up to the clients, the service life of equipment can be prolonged over 10 times under the same working conditions.

Corrosion resistance

High alumina ceramics are inorganic oxides with extremely stable molecular structure and no electrochemical corrosion, thus they can resist erosion of acid, alkali, salt solutions and organic Solvents.

Thermostability

Working temperature of high alumina ceramics can be as high as 1400℃.

Good self-lubricity

High alumina ceramics have the properties of self-lubricity and in adhesion, the roughness is only 1/6 that of steel pipes thus less flow Resistance.

Light weight

The density of high alumina ceramics is about 3.6g/cm3, which is only half that of steel, thus easy for construction and installation.

Ceramic tile lined pipe is composed of three layers: outer steel pipe layer, corundum layer, and ceramic glue layer. The inner ceramic layer is white from the surface. The ceramic is generally 95% ceramic, and the temperature is generally below 200°C.

At present, the common ceramic sheets lined with ceramic composite pipes are: ceramic block, dovetail mutual pressure, welding type, mosaic, card slot and so on. It has the characteristics of wear resistance and long service life.

Performance

Specifications

Ceramic tile technical indicators

Bimetallic composite steel pipe basic principles: outside the tube is responsible for the pressure and the role of rigid support pipe, liner bear the role of corrosion resistance.

The outer tube can be used according to the flow and pressure requirements of the conveying medium, choose the carbon steel pipe with different diameter and wall thickness, hot-dip galvanized steel pipe, straight seam welded pipe, spiral pipe, low pressure medium pipe, high pressure boiler, Oil cracking with seamless pipe, pipe and so on. Diameter from φ20-φ1020mm, wall thickness from 2.5-50mm.

Can be austenitic stainless steel 304,304 L, 316,316 L, copper-based alloy, nickel-based alloy, Hastelloy, titanium, titanium alloy, duplex stainless steel and other new high corrosion resistance alloy material. The lining wall thickness can be based on service life and welding process requirements from 0.3-4mm.

Will be assembled inside and outside the tube placed in the sink, the cluster of explosives placed in the lining liner axis, through the explosive instantaneous production of explosive force, causing the water pressure within the tank increased instantaneously, instantaneous increase in water pressure, Tube in the direction of outward expansion, outward expansion of the liner under the action of water pressure, the expansion of the outer surface of the outer tube, and under the action of water pressure, with the external tube continued to expand until the pressure disappeared ; And the outer tube in the axial direction inward contraction, the final composite forming.

The ceramic tile is pasted on the steel pipe with high temperature wear-resistant glue to play a wear-resistant role, and the pipe is generally white. Generally used for large diameter pipes.

The ceramic tile is pasted on the steel pipe with high temperature wear-resistant glue to play a wear-resistant role, and the pipe is generally white. Generally used for large diameter pipes.

Bends and other profile sections can be clad in whole and this process has changed the traditional practice to fabricate bend and other profile sections by drawing polyline without changing flow pattern of material inside piping, greatly reducing conveyance resistance of material.

| No. | Process | Standard | Inspection |

|---|---|---|---|

| 1 | Cleaning the inner surface of the fitting | Clean up all the rubbish and floating ash on the inner surface of construction equipment and pipe fittings. | Checked by the construction supervisor. |

| 2 | Rust removal, oil removal, paint removal | The rust, grease, and paint on the bonding surface must be completely removed without leaving any traces. Use iron sand skin, angle grinder, and soft sand skin to polish to see the metallic luster. After cleaning, wipe the surface with a cloth until there is no trace of dirt. | After the inspection and acceptance by the quality inspector, the construction of the next process can be carried out. |

| 3 | Formulated Adhesives | It must be measured in strict accordance with the prescribed proportion, and how much should be used; it must be stirred evenly, and the overall mixing should not be less than 4 times; if the mixed embedded material is added, the binder must be mixed well before adding the mixture and mixing Not less than 3 times. | Assigned by designated personnel. |

| 4 | Repair of the adhesive surface | If there are potholes on the pasting surface, especially if there are large potholes on the pasting surface of the old equipment, the wear-resistant ceramic sheet must be gradually filled with embedded materials. | After the inspection and acceptance by the quality inspector, the construction of the next process can be carried out. |

| 5 | Paste wear-resistant ceramic tiles | There should be no dust or dirt on the surface of the ceramic tiles. The surface of the repaired inlay material must be leveled. The pasting surface must be wiped again. Scrape the adhesive on the pasting surface for 1-2 times and scrape it flat. Scrape the back of the ceramic sheet for 1 It is necessary to ensure that there is a certain thickness of uniform adhesive available for pasting. | Checked by the person in charge of the construction of the pasted ceramic tiles. |

| 6 | Repair of gaps and corners between ceramic tiles | The gaps exceeding 3 mm must be repaired with wear-resistant and anti-corrosion fillers, the edges and corners must be neat, and the bevels must be trimmed with special ceramic tiles and then filled with fillers. | After the repair, the person in charge of the construction and the quality inspector will conduct a comprehensive quality inspection, and submit it to Party A for acceptance after passing the inspection. |

| 7 | Maintenance time | After construction and repair are completed, it can be put into use after natural maintenance for more than 12 hours after acceptance by Party A. |

Need to inquire about our products? Fill out the form below and our staff will be in touch!

Q: How long is your delivery time?

A: The delivery time of customized products is generally 25 35 days, and non customized products are generally shipped within 24 hours after payment.

Q: Do you provide samples? Is it free?

A: If the value of the sample is low, we will provide it for free, but the freight needs to be paid by the customer. But for some high value samples, we need to charge a fee.

Q: What are your payment terms?

A: T/T 30% as the deposit,The balance payment is paid in full before shipment

Q: What is the packaging and transportation form?

A: Non steaming wooden box and iron frame packaging. Special packaging is available according to customer needs. The transportation is mainly by sea.

Q: What is your minimum order quantity?

A: There is no minimum order quantity requirement. Customized products are tailor made according to the drawings provided by the customer.