Our team is highly trained and experienced in servicing and producing all types of steel supplies. Need help or have a question?

sales@abrasionresistantpipe.com

Tel.: +8621-3378-0199

Our team is highly trained and experienced in servicing and producing all types of steel supplies. Need help or have a question?

sales@abrasionresistantpipe.com

Tel.: +8621-3378-0199

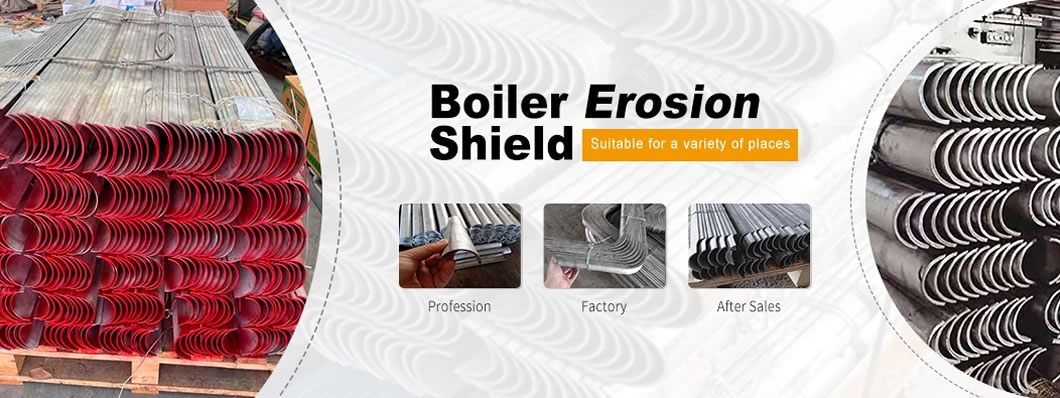

The half round shield for boiler tube is formed by pressing on a press or bending it on a tube bender with special abrasives.

The production process of Tubes Erosion Shields is mainly based on casting in the early stage, but the production period of cast Boiler Tubes Erosion Shields is long (20-50 days), the welding performance is poor, the welding is not strong, and the cost is high (more than twice that of pressed Stainless Steel Erosion Shields) ; Now the production of anti-wear tiles is made by high-pressure presses and professional molds. The production time is short, the welding performance is good, the welding should not fall off, the surface is smooth, and the appearance is beautiful.

The half round shield for boiler tube is formed by pressing on a press or bending it on a tube bender with special abrasives.

The cross-sectional shape of boiler tubes shields is mostly semi-circular (180 degrees), and there are also 120-160 degrees. It is mainly used on finned tubes (water-cooled walls); boiler tubes erosion shields are divided into direct wear-resistant shields, in-curve anti-wear shields, outer-curve anti-wear shields, side-curve anti-wear shields, s-curve anti-wear shields, etc.

The length of the straight anti-wear shields ranges from 20mm to 3000mm, and the general length of 1000-2000mm is commonly used. The anti-wear shields with bends generally requires a processing drawing and the following parameters should be on the drawing: outer diameter of the pipe used, bending of the pipe Radius R (to the center of the pipe), the degree of bending angle, and the length of the straight sections on both sides of the arc segment of the wear-resistant shields.

The most basic parameter of boiler tubes shields is the outer diameter of the tube used (that is, the inner diameter of boiler tubes erosion shields). The main specifications of the tube are: 32, 38, 42, 44.5, 48, 51, 57, 60, 63.5 , 76, 89mm, etc . the inner diameter of the boiler tubes erosion shields is usually 1-3mm larger than the outer diameter of the tube used, depending on the actual requirements.

To ensure the accuracy of the material. Positive Material Identification (PMI) of stainless steel sheets for tube shields is critical to verifying the grade and composition of stainless steel before it goes into production.

Tube shields from us are manufactured to exacting standards. Advanced equipment and material handling capabilities permit us to offer the fastest turnaround times anywhere.

The current production process for tube shields is to use high-pressure presses and professional moulds for pressing.

The production time is short, the welding performance is good, the welding seam does not fall off, the surface is smooth and the appearance is beautiful. The arc-shaped wear-resistant tile is pressed on a press or bent on a pipe bender with a special mould.

Different types of stainless steel are selected according to the specific conditions of different working conditions. Common materials are: TP321 (Cr18Ni9Ti), TP309S (Cr23Ni13), 1Cr20Ni14Si2, TP310S (Cr25Ni20), 1Cr25Ni20Si2, and some low temperature areas (such as low temperature superheater, low temperature reheater) are made of 1Cr13, 1Cr6Si2Mo and other materials.

Different types of stainless steel are selected according to the specific conditions of different working conditions. Common materials are: TP321 (Cr18Ni9Ti), TP309S (Cr23Ni13), 1Cr20Ni14Si2, TP310S (Cr25Ni20), 1Cr25Ni20Si2, and some low temperature areas (such as low temperature superheater, low temperature reheater) are made of 1Cr13, 1Cr6Si2Mo and other materials.

The boiler was originally designed to be accurate. Different materials have different temperature resistance and mechanical strength. 1Cr13, 1Cr6Si2Mo generally has a temperature resistance of 600 ℃ or less.

| Material(Grade) | Temperature resistance | Yield strength | Tensile strength | Elongation | HB | HRB | HV |

|---|---|---|---|---|---|---|---|

| 1Cr18Ni9Ti | 925 ℃ | ≥205MPa | ≥520MPa | ≥40% | ≤187 | ≤90 | ≤200 |

| Cr23Ni13 | 1095 ℃ | ≥205MPa | ≥520MPa | ≥40% | ≤187 | ≤90 | ≤200 |

| 1Cr20Ni14Si2 | 1095 ℃ | --- | ≥590MPa | ≥40% | --- | --- | --- |

| Cr25Ni20 | 1150 ℃ | ≥205MPa | ≥520MPa | ≥40% | ≤187 | ≤90 | ≤200 |

| 1Cr25Ni20Si2 | 1150 ℃ | --- | ≥540MPa | ≥35% | --- | --- | --- |

Tube shields are custom made to fit perfectly to straight sections, curved sections and even finned and specialised tubing.

Boiler tube erosion shields, also known as anti-corrosion shields, anti-wear plate, anti-wear protection shields, anti-wear cover plate, anti-corrosion cover plate, boiler climbing pipe, anti-wear pressure plate, etc. , which are used in combination with snap rings.

Boiler tube erosion shields are produced using a high-pressure press and professional mould pressing. The production time is short, the welding performance is good, the welding should not fall off, the surface is smooth, and the appearance is beautiful. Boiler tube erosion shields with bends are formed by pressing on a press or bending with a special abrasive on a tube bender.

Boiler tube shields are designed to eliminate major maintenance and downtime costs from boiler and condenser tube failure.

The service life of boiler tube erosion shields is different in different types of boilers and different use parts. The normal service life is a period of overhaul (3-5 years) for the boiler. Generally, some boilers will be replaced or retrofitted every time the boiler is overhauled. The main replacements are those of the boiler tube erosion shields that are severely thinned and exceeded the standard; those that were not firmly detached during the boiler operation during the previous installation. According to the wear of the boiler tube erosion shields during replacement, if the thickness is severely reduced, it needs to be replaced, the deformation is severe, and those that cannot protect the tube also need to be replaced. In addition, some boiler tubes are not equipped with boiler tube erosion shields, but during the boiler inspection, it is found that the tubes have a tendency to wear and thinning. Generally, boiler tube erosion shields are also installed to prevent further wear of the tubes and cause serious consequences such as boiler explosions.

The service life of boiler tube erosion shields is different in different types of boilers and different use parts. The normal service life is a period of overhaul (3-5 years) for the boiler. Generally, some boilers will be replaced or retrofitted every time the boiler is overhauled. The main replacements are those of the boiler tube erosion shields that are severely thinned and exceeded the standard; those that were not firmly detached during the boiler operation during the previous installation. According to the wear of the boiler tube erosion shields during replacement, if the thickness is severely reduced, it needs to be replaced, the deformation is severe, and those that cannot protect the tube also need to be replaced. In addition, some boiler tubes are not equipped with boiler tube erosion shields, but during the boiler inspection, it is found that the tubes have a tendency to wear and thinning. Generally, boiler tube erosion shields are also installed to prevent further wear of the tubes and cause serious consequences such as boiler explosions.

On the heating surface of superheated and the economizer tube bundle of the boiler, in order to prevent the pipe from being worn by high temperature flue gas washing, boiler tube erosion shields are mostly arranged on the outer side of the pipe in the direction of flue gas flow. The elbow erosion shields solves the abrasion problems of water wall tubes, superheater tubes, economizer tubes and reheater tubes in the furnace, and provides a guarantee for the long-term and reliable operation of CFB boiler. With the increase of CFB boiler products, the type and quantity of the elbow erosion shields will increase.

Tube erosion shields are mainly used on the windward side of the heating surface of the boiler, such as superheaters, reheaters, economizers, and water-cooled wall pipes. The main role is to protect the heating surface of the boiler pipes, reduce pipeline wear, and increase the heating surface of the pipes.

Erosion shields are used to protect boiler tubing from the highly erosive effects of high temperatures and pressures thereby greatly extending tube life.

We offer shielding for tubing, covering straight, bent and finned sections, as well as the clips that hold these in place.

In the long term, these shields more than pay for themselves, preventing the costly replacement of tubing and avoiding the downtime that results from tube breakdown and leaks.

In general, most of them are called “wear-resistant tile” and “wear-resistant cover plate”. Erosion Shields are special boiler accessories.

Generally, most of them are used in power station boilers, small boilers are used less, and some coal chemical industries will also use them.

Need to inquire about our products? Fill out the form below and our staff will be in touch!

Q: How long is your delivery time?

A: The delivery time of customized products is generally 25 35 days, and non customized products are generally shipped within 24 hours after payment.

Q: Do you provide samples? Is it free?

A: If the value of the sample is low, we will provide it for free, but the freight needs to be paid by the customer. But for some high value samples, we need to charge a fee.

Q: What are your payment terms?

A: T/T 30% as the deposit,The balance payment is paid in full before shipment

Q: What is the packaging and transportation form?

A: Non steaming wooden box and iron frame packaging. Special packaging is available according to customer needs. The transportation is mainly by sea.

Q: What is your minimum order quantity?

A: There is no minimum order quantity requirement. Customized products are tailor made according to the drawings provided by the customer.