Our team is highly trained and experienced in servicing and producing all types of steel supplies. Need help or have a question?

sales@abrasionresistantpipe.com

Tel.: +8621-3378-0199

Our team is highly trained and experienced in servicing and producing all types of steel supplies. Need help or have a question?

sales@abrasionresistantpipe.com

Tel.: +8621-3378-0199

Duplex stainless steel is a type of austenitic stainless steel that comprises of nickel and chromium majorly, along with other elements like nitrogen and molybdenum.

Duplex Steel pipes have two structural phases viz. Austenitic and Ferritic. Mechanical properties of Duplex Steels are outstanding. Also, the corrosion resistance properties in these pipes is excellent.

When compared to regular austenitic and ferritic steel grades, Duplex Steels are stronger. In comparison to only ferritic steels the ductility and toughness of Duplex steel pipes is much better. Chloride pitting and crevice corrosion is not a problem for these pipes as the nitrogen, chromium and molybdenum content make it highly resistant to it. These duplex steel pipes are immune to stress-corrosion cracking. Duplex Steel pipes are added with less amounts of nickel and molybdenum in comparison to other austenitic grades, making them highly cost effective. The increased tensile strength helps in altering the sectional thickness of these pipes against normal austenitic steels. Duplex Steel pipes find usage in many applications such as processing plants, brewing tanks, hot water tanks and more. This is due to the stress-corrosion cracking resistance of the steel. The relatively low costs, general corrosion resistance and higher strength make these duplex steel pipes more popular.

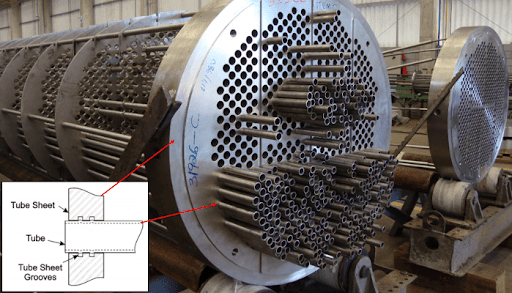

Duplex Stainless Steel is a type of steel containing the high amount of chromium and minimum amount of nickel. It provides great strength and resistance to corrosive environments. It is used in desalination plants, heat exchangers, and marine processes.

This stainless steel alloy offers good resistance to localized as well as to uniform corrosion. The duplex microstructure of the alloy contributes to the high strength and high resistance to stress corrosion cracking. It has good weld ability and offers many beneficial properties of ferritic and austenitic steels combined.

Duplex Stainless Steel gives very good resistance to pitting and crevice corrosion and has high resistance to stress corrosion cracking and corrosion fatigue. It displays high mechanical strength and also provides good abrasion and erosion resistance. It is used in chemical, Oil and gas and marine industries. Other uses if the duplex stainless steel is in pollution control equipments, pulp & paper manufacturing, seawater desalination plants and in flue-gas cleaning to name a few.

Steel Grade:

Typical Properties:

Specification:

Duplex stainless steel is a very useful metal that is used the world over. It gets its name from the fact that it consists of two different grades of metal.

Essentially, Duplex is a Fe-Ni-Cr alloy that has a two-phase ferritic-austenitic stainless-steel microstructure when it is at room temperature.

Duplex steels are characterised by high chromium (19–28%) and molybdenum (up to 5%) and lower nickel contents than austenitic stainless steels. The most used duplex stainless steels are the 2205 (22% Chromium, 5% Nickel) and the 2507 (25% Chromium, 7% Nickel); 2507 is known as “super duplex” due to its higher resistance to corrosion.

The advantage of combining ferritic and austenitic grades is that the resultant metal has a metallurgical structure that consists of two phases and therefore benefits from the properties of both microstructures.

These properties make duplex steel highly sought after in heavy industries, like oil and gas nuclear and chemical processing.

The origin of Duplex steels can be traced back to the 1920s, with the first cast being made in Sweden in 1930. However, the popularity of using duplex only started to rise around 30 years ago when steelmaking technology became more advanced.

The two types of metals used to make Duplex – austenitic and ferritic – are both fit for purpose in many types of scenarios but they both have weaknesses that prevent them from being used more widely.

Austenitic has a low strength and a low resistance to stress corrosion cracking, while ferritic also has a low strength, poor weldability and poor low temperature toughness.

Producing a chemical composition that combines austenitic and ferritic results in a metal that has a higher strength, good weldability, good toughness and resistance to stress corrosion cracking.

The high strength of duplex stainless steel means that The range of 0.2% PS for current duplex grades is from 400 – 550 MPa. This can lead to reduced section thicknesses and, subsequently, reduced weight. This advantage is particularly significant for applications such as pressure vessels, storage tanks and structural Applications like bridges.

However, one of the negatives is that Duplex is brittle at extreme temperatures which means that its use is normally restricted to a maximum temperature of 300 degrees and minimum temperature of –50 degrees.

When creating duplex stainless steels, the aim is to produce a 50/50 mixed microstructure of austenite and ferrite metals, although, in commercial alloys, the mix may be 40/60 respectively.

Interestingly, it is considered that we are still very much in the development phase of duplex steels, as different ratios of austenitic vs ferritic metals are still being tested.

Duplex stainless steel has an array of various benefits such as:

The extensive benefits of Duplex stainless steel mean that it can be used in many different applications such as:

| UNS No | S32750 |

|---|---|

| EN | 1.441 |

| AISI | 2507 |

| Carbon (C) | 0.03 |

| Silicon (Si) | 0.8 |

| Manganese (Mn) | 1.2 |

| Phosphorus (P) | 0.035 |

| Sulphur (S) | 0.02 |

| Chromium (Cr) | 24.0/26.0 |

| Molybdenum (Mo) | 3.0/3.5 |

| Nickel (Ni) | 6.00/8.00 |

| Nitrogen (N) | 0.24/0.32 |

| Other | Cu: 0.50 |

| DESCRIPTION | DUPLEX 2205 |

|---|---|

| Proof Stress 0.2% (MPa) | 450 |

| Tensile strength (MPa) | 620 |

| Elongation A5 (%) | 20 |

| Hardness | HB: 293 HRB: 96 (according to Rockwell C Scale) |

| UNS No | S32750 |

|---|---|

| EN | 1.441 |

| AISI | 2507 |

| Carbon (C) | 0.03 |

| Silicon (Si) | 0.8 |

| Manganese (Mn) | 1.2 |

| Phosphorus (P) | 0.035 |

| Sulphur (S) | 0.02 |

| Chromium (Cr) | 24.0/26.0 |

| Molybdenum (Mo) | 3.0/3.5 |

| Nickel (Ni) | 6.00/8.00 |

| Nitrogen (N) | 0.24/0.32 |

| Other | Cu: 0.50 |

| Density (Kg/m3) | 7810 |

|---|---|

| Magnetic Permeability (20°C) | 33 |

| Young’s Modulus (kN/mm2) | 199 |

| Specific Electrical Resistance, 20°C (µΩ.m) | 0.8 |

| Mean coefficient of thermal expansion, 20-300°C (m/m/oC) | 11.1 x 10-6 |

| Specific Heat, 20°C (J/kg.K) | 475 |

| Thermal conductivity, 20°C (W/m.K) | 14.2 |

| Fracture Toughness, kQ (MPa/m2) | 98 |

Duplex stainless steel

| Steel No. | Standard No. | Type | Chemical composition | Other | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| C | Si | S | P | Mn | Cr | Ni | Mo | Other | ób | ós | δ5 | HB | ||||

| 0Cr26Ni5Mo2 | GB1220 | Bar | 0.08 | 1 | 0.03 | 0.035 | 1.5 | 23-28 | 3-6 | 1-3 | 590 | 390 | 18 | 277 | ψ%:40 | |

| 0Cr26Ni5Mo2 | GB4237 | Plate | 0.08 | 1 | 0.03 | 0.035 | 1.5 | 23-28 | 3-6 | 1-3 | 590 | 390 | 18 | 277 | ||

| 0Cr26Ni5Mo2 | GB/T14976 | Pipe | 0.08 | 1 | 0.03 | 0.035 | 1.5 | 23-28 | 3-6 | 1-3 | 590 | 390 | 18 | |||

| 00Cr18Ni5Mo3Si2 | GB1220 | Bar | 0.03 | 1.3-2 | 0.03 | 0.035 | 1.2-1.6 | 18-19.5 | 4.5-5.5 | 2.5-3 | 590 | 390 | 20 | ψ%:40 | ||

| 00Cr18Ni5Mo3Si2 | GB4237 | Plate | 0.03 | 1.3-2 | 0.03 | 0.03 | 1.2-1.6 | 18-19.5 | 4.5-5.5 | 2.5-3 | N:0.1 | 590 | 390 | 20 | ||

| HDR | Q/SJB11-99 | Pipe | 0.03 | 1 | 0.03 | 0.035 | 2 | 23-26 | 4.5-7.5 | 2-3 | 650 | 450 | 27 | |||

Duplex stainless steels possess a mixed microstructure of ferrite and austenite. They contain a high chromium content of 22 wt.% – 25 wt.%, a molybdenum content of up to 5 wt.% and a low nickel content.

Duplex stainless steels exhibit roughly twice the strength of austenitic stainless steels and possess greater resistance to chloride stress corrosion cracking compared to austenitic stainless steels, albeit less so than ferritic. They exhibit toughness between that of ferritic and austenitic.

Examples & applications of duplex stainless steels

Due to these properties, duplex stainless steels are ideal for demanding environments where good mechanical properties are required in addition to good corrosion resistance. Common examples of duplex stainless steels include:

| Item | ASTM A213/A213M | ASTM A312/A312M | ||

|---|---|---|---|---|

| Grade | TP304 | TP304L | TP304 | TP304L |

| TP316 | TP316L | TP316 | TP316L | |

| TP317 | TP317L | TP317 | TP317L | |

| TP347 | TP310S | TP347 | TP310S | |

| TP309H* | TP310H* | TP317* | TP310H* | |

| TP321HΔ | TP321HΔ | |||

| Grade | C (max) | Si (max) | Mn (max) | P (max) | S (max) | Ni | Cr |

|---|---|---|---|---|---|---|---|

| TP 304 | 0.08 | 0.75 | 2 | 0.04 | 0.03 | 8-11 | 18-20 |

| TP 304H | 0.04-0.10 | 0.75 | 2 | 0.04 | 0.03 | 8-11 | 18-20 |

| TP 304L | 0.035 | 0.75 | 2 | 0.04 | 0.03 | 8-13 | 18-20 |

| TP 309S | 0.08 | 0.75 | 2 | 0.04 | 0.03 | 8-13 | 18-20 |

| TP 310S | 0.08 | 0.75 | 2 | 0.045 | 0.03 | 12-15 | 22-24 |

| TP 316 | 0.08 | 0.75 | 2 | 0.04 | 0.03 | 19-22 | 24-26 |

| TP 316L | 0.035 | 0.75 | 2 | 0.04 | 0.03 | 10-15 | 16-18 |

| TP 316Ti | 0.08 | 0.75 | 2 | 0.04 | 0.03 | 11-14 | 16-18 |

| TP 317 | 0.08 | 0.75 | 2 | 0.04 | 0.03 | 11-14 | 16-18 |

| TP 321 | 0.08 | 0.75 | 2 | 0.04 | 0.03 | 9-13 | 18-20 |

| TP 321H | 0.04-0.10 | 0.75 | 2 | 0.04 | 0.03 | 9-13 | 17-20 |

| TP 347 | 0.08 | 0.75 | 2 | 0.04 | 0.03 | 9-13 | 17-20 |

| TP 347H | 0.04-0.10 | 0.75 | 2 | 0.04 | 0.03 | 9-13 | 17-20 |

| Grade | Tensile Strength Min(Mpa) | Yeild Point Min(Mpa) | EL. Min(%) | Rockwell Max |

|---|---|---|---|---|

| TP 304 | 515 | 205 | 35 | 90 |

| TP 304H | 550 | 240 | 35 | 90 |

| TP 304L | 485 | 170 | 35 | 90 |

| TP 309S | 515 | 205 | 35 | 90 |

| TP 310S | 515 | 205 | 35 | 90 |

| TP 316 | 515 | 205 | 35 | 90 |

| TP 316L | 485 | 170 | 35 | 90 |

| TP 316Ti | 515 | 205 | 35 | 90 |

| TP 317 | 515 | 205 | 35 | 90 |

| TP 321 | 515 | 205 | 35 | 90 |

| TP 321H | 515 | 205 | 35 | 90 |

| TP 347 | 515 | 205 | 35 | 90 |

| TP 347H | 515 | 205 | 35 | 90 |

Heat treatment technology of stainless steel pipe surface

For the heat treatment technology of the surface of stainless steel pipes, non-oxidation continuous heat treatment furnaces with protective gas are generally used abroad for intermediate heat treatment and final heat treatment of finished products. As a bright surface without oxidation can be obtained, the traditional pickling process is eliminated. The adoption of this heat treatment process not only improves the surface of stainless steel pipes, but also overcomes the environmental pollution caused by pickling.

According to the manufacturer of stainless steel pipes, according to the current world development trend, bright annealing continuous heat treatment furnaces are basically divided into the following two types:

(1) Roller-type bright annealing heat treatment furnace.

This bright annealing furnace type is suitable for heat treatment of large-size and large-volume special-shaped stainless steel pipes, with an hourly output of above 1.0 Tons. The protective gases that can be used are high-purity hydrogen, decomposed ammonia and other protective gases. It can be equipped with a convection cooling system to cool the special-shaped stainless steel tube faster.

(2) Mesh belt type bright annealing heat treatment furnace.

This bright annealing furnace type is suitable for small-diameter thin-walled precision special-shaped stainless steel pipes. The hourly output is about 0.3 to 1.0 Tons. The length of the steel pipe can be up to 40m. It can also be used to process capillary tubes in coils. Equipped with convection cooling system for fast cooling. Using gas fuel or electric heating, various protective gases can be used. The stainless steel pipe after this furnace-type heat treatment has no scratches and good brightness surface.

Tensile test and hardness test of stainless steel pipe?

Tensile strength test is to make a sample of stainless steel pipe, pull the sample to break on a tensile testing machine, and then measure one or several mechanical properties, usually only the tensile strength, yield strength, elongation after fracture and section are measured Shrinkage. Tensile strength test is the most basic test method for mechanical properties of metal materials. Almost all metal materials require tensile test as long as they have requirements for mechanical properties. Especially for those materials whose shape is not convenient for hardness test, tensile strength test becomes the only means of testing mechanical properties.

The hardness test is to slowly press a hard indenter into the surface of the sample with a durometer under specified conditions, and then test the depth or size of the indentation to determine the hardness of the material. Hardness test is the simplest, fastest and easiest method in material mechanical property test. The hardness test is non-destructive, and there is an approximate conversion relationship between the material hardness value and the tensile strength value. The hardness value of the material can be converted into the tensile strength value, which has great practical significance.

Because the tensile strength test is not easy to test, and it is convenient to convert the hardness to the strength, more and more people only test the hardness of the material and less test its strength. In particular, due to the continuous advancement of hardness tester manufacturing technology and innovations, it is now possible to directly test the hardness of some materials that could not be directly tested before, such as stainless steel tube, stainless steel sheet and stainless steel strip. Therefore, there is a tendency for hardness tests to gradually replace tensile tests.

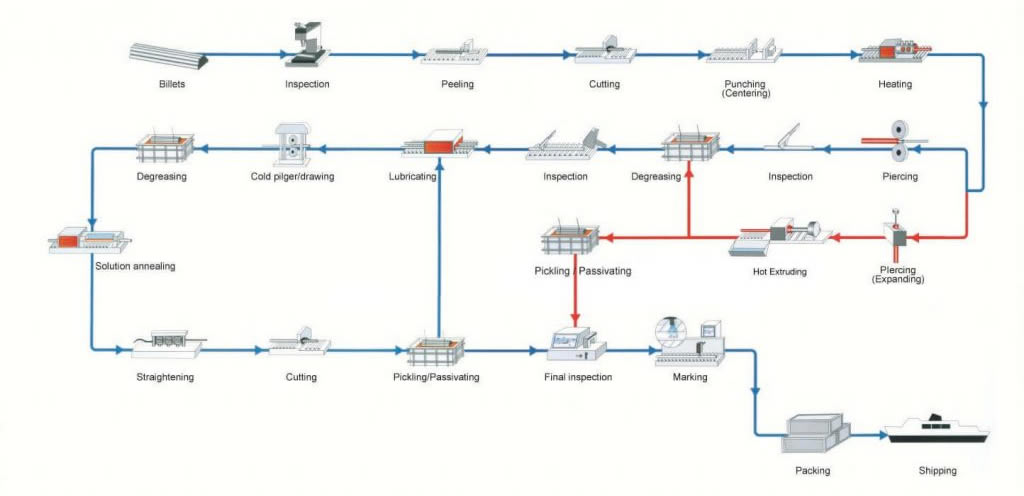

Our specialized process for seamless tubing manufacturing begins with either an extruded hollow tube or a solid bar drilled to our exacting specifications. The material is then reduced in size a number of times through various cold working techniques until it reaches the specific size, tolerances, and temper required by our customer. After each cold working cycle the tubes are cut, cleaned and heat treated in preparation for the next cold working step.

Pilfering

Pilfering reduces the size of the tube across three dimensions – outside diameter (OD), internal diameter (ID) and wall thickness. We roll a die set with a tapered groove across the outside of the tube while supporting the inside diameter using a taper-matched, hardened steel mandrel.

In a single cold working step, we can achieve a significant reduction in cross-sectional area while minimizing material loss and, most importantly, improving the material’s microstructure. Seamless tubes constitute the majority of volume processed by tube reducing or pilgering.

Cold Rolling

Like pilgering, tube rolling also uses compression to reduce the size of seamless tubes. However, while pilgering uses a pair of grooved, tapered dies to work the metal over a tapered mandrel, tube rolling utilizes one or two sets of rolls with constant cross-section grooves on the circumference of the tube.

Generally, the process employs a cylindrical mandrel with little or no taper. The rolls are driven by rack and pinion gears of different radii along profiled cams, completing multiple 360º rotations around the tube.

Cold rolling is a very precise method of reducing very thin walled and/or smaller diameter tubes, and is often used as the final cold working step. By rolling, we’re able to achieve exceptional control over dimensional tolerances and surface finish while also minimizing material loss and improving the metal’s microstructure.

Because it uses compression, tube rolling is well suited to processing unique metals like titanium and zirconium alloys.

Our cold rolling capabilities include both classic 2-roll (single roll set) tube rollers and an advanced 3-roll approach.

Cold Drawing

Typically used as the first form of size reduction for seamless tubes, cold drawing reduces the diameter by pulling the tube through a die that is smaller than the tube. In order to fit the tube into the die, one end is ‘swaged’ or ‘tagged’ thereby reducing the diameter of the leading end before drawing. Next, the narrowed end is passed through the die and clamped to a drawing trolley which pulls the tube through the die. After drawing the ‘tag’ is cropped from the tube end prior to cleaning.

Sink drawing

This is the simplest of the three drawing methods, as there is no tooling to support the ID surface. The tube is drawn through a die made of polished tool steel or industrial diamond, thereby reducing its inside and outside diameters. Our specialized lubrication and application techniques, combined with our proprietary die profiles, enable the OD surface to become smoother as the tube is drawn. Since the inside diameter is not constrained, the wall thickness of the tube will normally increase during drawing, and the ID surface finish will normally become rougher during a sink draw.

Rod drawing

Rod drawing is our most commonly used cold draw method, primarily for intermediate or in-process drawing stages, where both the outside diameter and wall thickness are reduced at the same time.

The tube is loaded over a hardened steel mandrel rod and both are then drawn through a die. This squeezes the tube onto the rod, reducing the outside diameter and thinning the wall simultaneously. The die and mandrel determine the size of the drawn tube, which is then slightly expanded by applying pressure to the outside of the tube so that the rod can be removed. Since larger reductions in cross-sectional area can be achieved by rod drawing, this method is used for mid-process stages to reduce tube sizes prior to the final drawing cycle.

Plug drawing

This type of drawing is used to achieve the best possible surface finish and the greatest control over both dimensions and final temper. The outside diameter and wall thickness of the tube are both reduced during plug drawing, as the tube travels through a die and over a stationary plug/mandrel made of high grade tool steel. The plug or mandrel has a polished surface and is attached to a fixed back rod, which is carefully positioned within the drawing die. The tube is loaded over the mandrel/back rod. As the tube passes through the die, the burnishing action of the metal flowing over the stationary plug imparts a high tolerance surface finish inside the tube.

When properly lubricated and prepared, the ID will show very few flaws and finishes of 16 RMS or better can be achieved. Plug drawing is normally chosen for the final draw stage because it achieves a high quality surface finish, exceptional dimensional control, and positive influence on tensile strength requirements.

Annealing

Annealing is used to soften the metal before further cold working or fabrication processes, and improves the overall metallurgical microstructure of the tube. During tube reduction or cold drawing, it can become hard and somewhat brittle. To be able to draw the tube again, stresses formed during cold working need to be removed to return the material to its normal state.

During annealing the tube is heated to a controlled temperature (up to 2100°F) and soak time. Through this process the tube remains in shape, but the grains in the structure of the tube reform into a regular unstressed pattern. The resulting annealed tube is softer and suitable for redrawing.

Our closely controlled annealing and heat treat processes are audited regularly by our nuclear, medical, and aerospace customers.

Straightening

Drawing and annealing generally results in some degree of bowing, producing a slight bend in the tubing. We use multiple roll mechanical straighteners in the first stage of finishing. The straightener applies pressure and flex to the product in order to remove bends or bows, resulting in a straightness level of 0.010” per foot, or better. Straightening can introduce slight changes to the size and mechanical properties of the tubing, so these aspects are very carefully controlled during the process.

There are probably hundreds of different methods for packing stainless pipe, and most of them have merit, but there are two principles that are vital for any method to work prevent rusting and Sea transportation security.

We inventory stainless steel grades that are readily used in manufacturing such as 304, 304L and 316/L to harder to find items such as 309H, 330 or 405 stainless.

Stainless steel pipe (tube) has excellent characteristics of corrosion resistance and smooth finishing. Stainless steel pipe (tube) is commonly used in demanding equipment like automobiles, food processing, water treatment facilities, oil and gas processing, refinery and petrochemicals, breweries and energy industries.

Stainless steel tube is typically measured by its outer diameter and can be used in a variety of applications including a number of structural applications. Stainless steel tubing is extremely durable and able to withstand corrosion. This tubing will not rust, even if exposed to the elements, heat, and other extreme conditions. Because of these factors, stainless steel tubing can be used for a wide variety of applications.

The stainless steel tubing that is supplied by SunnySteel can used in a variety of industries, including:

Considering the importance of outside and inside surface of stainless steel tubes for fluid power industry, Our mills are providing tubes that are free from scale, rust, seams, laps.

the main requirement for stainless steels is that they should be corrosion resistant for a specified application or environment. The selection of a particular “type” and “grade” of stainless steel must initially meet the corrosion resistance requirements.

Additional mechanical or physical properties may also need to be considered to achieve the overall service performance requirements.

Need to inquire about our products? Fill out the form below and our staff will be in touch!

Q: How long is your delivery time?

A: The delivery time of customized products is generally 25 35 days, and non customized products are generally shipped within 24 hours after payment.

Q: Do you provide samples? Is it free?

A: If the value of the sample is low, we will provide it for free, but the freight needs to be paid by the customer. But for some high value samples, we need to charge a fee.

Q: What are your payment terms?

A: T/T 30% as the deposit,The balance payment is paid in full before shipment

Q: What is the packaging and transportation form?

A: Non steaming wooden box and iron frame packaging. Special packaging is available according to customer needs. The transportation is mainly by sea.

Q: What is your minimum order quantity?

A: There is no minimum order quantity requirement. Customized products are tailor made according to the drawings provided by the customer.