Our team is highly trained and experienced in servicing and producing all types of steel supplies. Need help or have a question?

sales@abrasionresistantpipe.com

Tel.: +8621-3378-0199

Our team is highly trained and experienced in servicing and producing all types of steel supplies. Need help or have a question?

sales@abrasionresistantpipe.com

Tel.: +8621-3378-0199

We offer cast basalt tiles for coal bunkers and chutes. These cast basalt tiles are bedded as well as jointed in cement/special bonding agents like resins depending upon application. These tiles mostly find application in automotive industry and are designed to provide long-lasting lining and enhancement to involved operational life cycle for both plant as well as equipment.

Basalt is a volcanic stone, used in architecture for centuries. Although basalts boast the durability of a granite, they have the consistent coloration, markings and subtlety of a limestone.

Basalt lining tiles are used in floor covering, bunker’s walls and outlets, silos and other tanks using storage of bulk materials that are strong abrasion. Strong friction wear is caused when emptying the bunker and silos and, in addition, impact wear occurs during the filling process. This abrasion sometimes destroys cement bunker walls within a relatively short time. In practice, cast basalt tiles wear-resistant linings have proved to be an economical solution. The walls are lined with hexagonal or rectangular tiles. Circular bunker and silos are lined with radial rectangular or hexagonal form pieces, exactly fitting the respective circumference.

Rectangular and hexagonal tiles are used in the coating of large areas like bunker, silos and tank.

Advantages:

Cast basalt is a durable, resistant, and reliable and widely used manufacturing material being used in variant construction projects and industries. The linings made from cast basalt are strong and have long lasting effects. This is why most of the industries prefer using cast basalt linings in most of their manufacturing and processing operations.

We offer cast basalt tiles for coal bunkers and chutes. These cast basalt tiles are bedded as well as jointed in cement/special bonding agents like resins depending upon application. These tiles mostly find application in automotive industry and are designed to provide long-lasting lining and enhancement to involved operational life cycle for both plant as well as equipment.

| SiO2 | Al2O3 | Fe2O3 | TiO2 | CaO | MgO | K2O | Na2O | FeO | P2O5 | MnO |

|---|---|---|---|---|---|---|---|---|---|---|

| 42-45% | 13-16% | 13-14% | 0.022 | 10-12% | 10-11% | 0.045 | 0.045 | 13-14% | <1% | <1% |

| NO. | ITEM | PERFORMANCE VALVE |

|---|---|---|

| 1 | Specific gravity | 2.9-3.05gm/cc |

| 2 | Compressive strength | 3000-4500kg per sq cm(min) |

| 3 | Bending strength | 300kg per sq cm(min) |

| 4 | Water Absorption | 0 |

| 5 | Solubility in Acids | 0.006 |

| 6 | Hardness | 8(MIN.)Moh Scale |

| 7 | Modules of elasticity | 11.1×104N/mm2 |

| 8 | Expansion coefficient (room temperature to 60°C) | 0.75×10-5/K |

| 9 | Thermal Conductivity | 1.15W/mk |

| 10 | Special Heat Capacity | 0.8kj/Kg.K |

| 11 | Highest Temperature For application | 350°C |

Advantages:

* Utilizing Cast Basalt enhances and improves operational life of plants.

* These are best suited for jobs where extensive cutting is needed.

* We can also deliver pre-cut tailored tiles based on the considerations of vibration, impact and other factors at client’s end.

| Thickness (mm) | Length * Width (mm) |

|---|---|

| 16-20 | < 200 |

| 20-30 | < 300 |

| 30-50 | < 400 |

Combined with the cast basalt production technology. We can manufacture cast basalt tiles according to various sizes and shapes.

Combined with the cast basalt production technology. We can manufacture cast basalt tiles according to various sizes and shapes.

Ultra-thin cast slate: the thinnest 12mm

The self-developed ultra-thin Cast basalt tile is a new product of the international advanced level.

Other than automobiles, some of the other industries where these are used in include:

Cast basalt tiles is mainly used in thermal power plants, steel mills, mines and other parts with heavy wear, such as raw coal bunkers, mine bins, coal unloading trenches, hoppers, ore troughs, flotation machines, chutes and other parts.

lined with cast slate, generally 25-30mm (high chromium steel is best used for coal drop points);

Cast basalt pipes owing to an excellent performance of abrasive and corrosion resistance .It may be used as the liner of pipeline for hydraulic,pneumatic of conveyance of material and corrosion materials or slurry.We can offer the basalt pipes with nominal diameter of 40mm-800mm.

Cast Basalt can be used for the lining of pipework, chutes, bunkers, cyclones, and hoppers. It has become the global standard in areas such as ash slurry pipework, often used at fossil-fuel power stations. It is an all-round cost-effective and adaptable lining material that extends the life of equipment in the pipe or tile form where affected by erosion.

Cast Basalt is well-proven in a variety of industries as a cost-effective, long-lasting lining material used to extend the operating life of equipment manufactured or lined with lower-wearing materials such as steel, cast iron, rubber, and polyurethane.

Cast basalt lined steel pipe, as both a wear—resistant and corrosion—resistant materials, the transport properties of wear or corrosion of materials, after thirty years of practical verification, cast basalt lined steel pipe can be well done.

Cast basalt is also used in cement plants for making air separators, chain conveyor, silica hoppers, nozzles, coal hoppers, cement hoppers, cyclones, raw mill ducts, chutes, thick slurry lines, mixers, grate cooler housing, coal ventury etc.

Cast basalt pipes have an excellent performance of abrasive resistant and corrosion resistant, can be used as the pipeline lining in conveying wearable materials and corrosion materials. Such as: electric power plant, chemical plant, metallurgy industry, mine and so on.

Cast Basalt Composite Pipes Used for Years

Cast basalt pipe adopts foam packaging, then in accordance with the specifications to put them into wooden cases, sometimes they can be directly loaded into the compartment or container.

Cast basalt pipe adopts foam packaging, then in accordance with the specifications to put them into wooden cases, sometimes they can be directly loaded into the compartment or container.

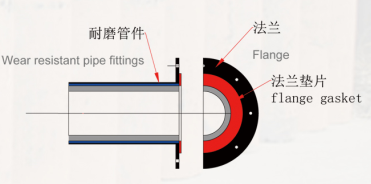

Cast basalt lined pipes and fittings can be supplied with different and connections as per the design requirement to suit the site conditions and easy installation.

As a standard production, we supply flanged components according to DIN, with at least one movable flange for easy mounting, but pipes with plain ends or for custom coupling are also available. Flange Connection Is One Kind Of Common Pipeline Installation Connections. By Two Pieces Of Flanges, Pipeline, Valve, Equipments Are Connected And It Forms A Tight Piping System. When Pipeline Pressure Is Larger, Flange Connection Is Priority Selection. Flanges Have Lots Of Different Sizes. Flange Size Is Determined According To Pipeline Normal Diameter And Pipeline Operation Pressure.

The parameters of the outside steel pipe will be decided according to the working pressure of the system. The connection of the pipes and fitting will be of flange connections, easy—flexible joint connection or by welding.

By two pieces of flanges, pipeline, valve, equipments are connected and it forms a tight piping system. When pipeline pressure is larger, flange connection is priority section. Flanges have lots of different sizes.

Flange size is determined according to pipeline normal diameter and pipeline operation pressure.

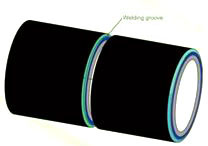

It suits short Distance Pipeline System Without Maintenance. It Is One Kind Of Common Installation Connections. It Requires Installation Personnel Higher Welding Ability. It Also Restricts By Welding Site, Distance, Welding Positions. Welding Connections Is Inconvenient In Later Maintenance.

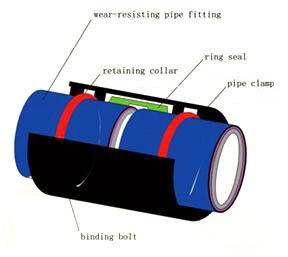

It Is One Of High Efficient And Rapid Installation Connection. I T Has The Below Characteristic: Easily Install And Disassemble, Fast Installation, Temperature Adjustable Compensation Function, Saving The Necessary Expansion In Long Pipeline. Easy-Flexible Joint Also Has Angle Compensation Characteristic. At Smaller Angle Turning Points, Easy-Flexible Joint Can Be Instead Of Bends And Adjust Angle.

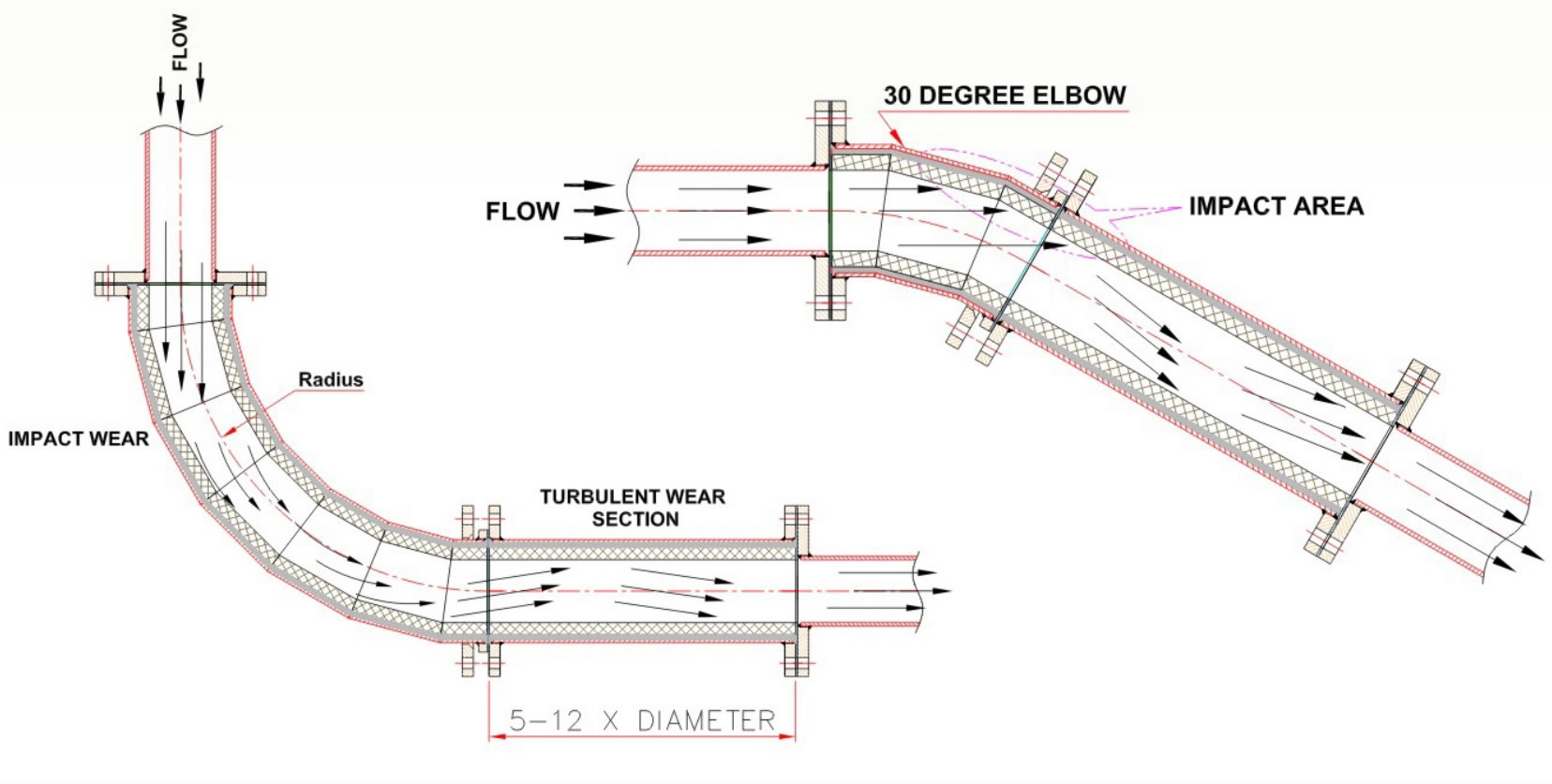

1. The bend radius should be minimum 3 times of the nominal bore.

2. At discharge end of each bend, cast basalt lined straight pipe of length 5 to 12 times the nominal bore must be used.

Need to inquire about our products? Fill out the form below and our staff will be in touch!

Q: How long is your delivery time?

A: The delivery time of customized products is generally 25 35 days, and non customized products are generally shipped within 24 hours after payment.

Q: Do you provide samples? Is it free?

A: If the value of the sample is low, we will provide it for free, but the freight needs to be paid by the customer. But for some high value samples, we need to charge a fee.

Q: What are your payment terms?

A: T/T 30% as the deposit,The balance payment is paid in full before shipment

Q: What is the packaging and transportation form?

A: Non steaming wooden box and iron frame packaging. Special packaging is available according to customer needs. The transportation is mainly by sea.

Q: What is your minimum order quantity?

A: There is no minimum order quantity requirement. Customized products are tailor made according to the drawings provided by the customer.