Our team is highly trained and experienced in servicing and producing all types of steel supplies. Need help or have a question?

sales@abrasionresistantpipe.com

Tel.: +8621-3378-0199

Our team is highly trained and experienced in servicing and producing all types of steel supplies. Need help or have a question?

sales@abrasionresistantpipe.com

Tel.: +8621-3378-0199

09CrCuSb seamless pipe, 09CrCuSb steel pipe, 09CrCuSb seamless tube is the most ideal steel materials in sulphuric and acid corrosion surroundings at low temperature. 09CrCuSb seamless pipe also called as ND alloy seamless pipe which mainly used power plant,heat exchangers,oil plants to resistance higher Sulphuric corrosion.

09CrCuSb seamless pipe, 09CrCuSb steel pipe, 09CrCuSb seamless tube is the most ideal steel materials in sulphuric and acid corrosion surroundings at low temperature. 09CrCuSb seamless pipe also called as ND alloy seamless pipe which mainly used power plant,heat exchangers,oil plants to resistance higher Sulphuric corrosion.

①GB 150.2-2011 “Pressure Vessel Part 2: Materials”

②NB/T 47019-2011 “Technical conditions for ordering boiler and heat exchanger tubes”

③SH/T 3096-2012 “Principle of Material Selection for High Sulfur Crude Oil Processing Equipment and Pipeline Design”

Composition specification (GB 150.2-2011)

| C | ≤0.12 | Cr | 0.70~1.10 |

| Si | 0.20~0.40 | Cu | 0.25~0.45 |

| Mn | 0.35~0.65 | Sb | 0.04~0.10 |

| P | ≤0.030 | S | ≤0.020 |

Mechanical Property

| Nominal Thickness

(mm) |

Tensile Strength

Rm(MPa) |

Yield Strength

ReL(MPa) |

Elongation

A(%) |

| ≤8 | 390~550 | ≥245 | ≥25 |

Corrosion resistance

In sulfuric acid of medium-temperature and medium concentration, ND steel is passivated due to dissolution, and a passivation layer rich in alloy elements such as Cu, Cr, Sb (antimony, sound: tī) is formed on the surface of the steel and has a high Sulfuric acid corrosion resistance.

Corrosion rate comparison between ND steel and other steels (70℃-50% H2SO4 solution)

| Type of Steel | Corrosion Rate

mg/(cm2h) |

Times |

| ND (09CrCuSb) | 7.3 | 1 |

| A3 (Q235B) | 103.5 | 14.18 |

| CORTEN-A | 63 | 8.63 |

| CR1A | 13.4 | 1.84 |

| 321 | 21.7 | 2.97 |

| S-TEN 1 & 2 | 27.4 | 3.75 |

For the corrosion resistance, GB 150.2-2011 stipulates: The steel pipe shall be tested for corrosion resistance, and one sample shall be taken from each of the two steel pipes in each batch, and each sample shall be a pipe length of 10 mm. Soak in a H2SO4 solution with a mass fraction of 50% at a constant temperature of 70°C (±2°C) for 24 hours. The average value of the corrosion rate of the two samples is not greater than 80g/m2×h or 140g/m2×h, the specific indicators are indicated in the order contract.

| Steel grade | 09CrCuSb(ND steel) | CRIR(Japan) | 1Cr18Ni9 | Corten | STEN(Japan) | A3(Q235B) |

| Corrosion rate | 7.30 | 13.40 | 21.70 | 63.00 | 27.4 | 103.50 |

| multiple | 1 | 1.84 | 2.97 | 8.63 | 3.75 | 14.11 |

ND steel pipe (09CrCuSb) shall be subject to corrosion resistance test. One sample shall be taken from each batch of two steel pipes, and each sample is a 10 mm long pipe section. Soak in 50% H2SO4 solution at 70 ℃ (± 2 ℃) for 24 hours. The average corrosion rate of two samples shall not be greater than 80g / ㎡ * h or 140g / ㎡ * h, and the specific index shall be indicated in the order.

The carbon equivalent of 09CrCuSb is moderate, the content of S and P is not high, so its welding performance is good, preheating is not necessary during welding, and heat treatment is not required after welding ND steel special NDS electrode is used for welding.

Specification:

| Specification | Specification |

| 19*2-4mm | 76-114 * 4-10mm |

| 25 * 2-4mm | 133-140 * 6-14mm |

| 32 * 2-5mm | 159-219 * 21-35mm |

| 38-42 * 3-5mm | 273-325 * 7-50mm |

| 51-63 * 3-5mm | 356-630 * 10-20mm |

09CrCuSb (ND steel) steel is developed for coal-fired boilers, oil-fired boilers; heat exchangers for electric furnaces, pipes, chimneys, boiler air preheaters, economizers, heat exchangers, condensing coolers, evaporators, etc. Hot-rolled steel sheets and steel pipes with excellent resistance to sulfuric acid dew corrosion. Its superior resistance to sulfuric acid dew point corrosion and very high cost performance is the best material that can completely replace stainless steel and surpass stainless steel (in terms of sulfuric acid dew point corrosion resistance). ND steel has great economic significance, in line with today’s high efficiency, longevity and energy saving. “Green” concepts such as environmental protection and national development policy orientation.

Advantage of 09CrCuSb (ND steel)

ND steel, 09CrCuSb steel, is the most ideal steel for “sulfuric acid resistant low temperature dew point corrosion” at home and abroad. ND steel is widely used in the manufacture of economizers, air preheaters, heat exchangers and in high sulfur flue gas. Equipment such as evaporators, used to resist corrosion of sulfur-containing flue gas dew point. ND steel also has the ability to resist chloride ion corrosion. The main reference index of ND steel pipe (soaked in 50% H2SO4 solution at 70 °C for 24 hours) is higher than that of carbon steel and stainless steel.

| Steel Grade | Corrosion Rate (mg/cm².h) | Multiple |

| 09CrCuSb (ND) | 7.3 | 1 |

| Corten-A | 63 | 8.63 |

| CRIA(Japan) | 13.4 | 1.84 |

| A3(Q235B) | 103.5 | 14.18 |

| TP321(1Cr18Ni9) | 21.7 | 2.97 |

*For the corrosion resistance, GB 150.2-2011 stipulates: The steel pipe shall be tested for corrosion resistance, and one sample shall be taken from each of the two steel pipes in each batch, and each sample shall be a pipe length of 10 mm. Soak in an H2SO4 solution with a mass fraction of 50% at a constant temperature of 70°C (±2°C) for 24 hours. The average value of the corrosion rate of the two samples is not greater than 80g/m2×h or 140g/m2×h. The specific indicators are indicated in the order contract.

09CrCuSb seamless steel pipe is widely used in the manufacture of economizer, air heat preheater, heat exchanger, evaporator and other equipment serving in high sulfur gas, which is used to resist condensation corrosion of sulfur-containing flue gas. It is characterized by resistance to low temperature sulfuric acid dew point corrosion of flue gas below 200 ° C. It is a new clean energy-saving product.

The market price of the special sulfuric acid dew point corrosion resistant pipe for 09CrCuSb boiler heat exchanger is about 9000 yuan per ton, only 40% of the price of stainless steel pipe of the same specification. When it is used in sulfur-containing medium, its corrosion resistance is no less than that of stainless steel, and the corrosion rate is 3.481mg/cm2. H (34.81g / m2. H) in sulfuric acid solution of 70 ℃ and 50%. The corrosion resistance of ND steel (09CrCuSb) is more than 3 times that of 321 stainless steel and 7 times that of 20g. It can be seen that ND steel is the first choice material for the experimental chemical plant in the environment of sulfur-containing medium.

ND steel is currently the most ideal steel for “sulfuric acid low-temperature dew point corrosion resistance” at home and abroad, and its seamless steel tubes are widely used in the manufacture of economizers, air preheaters, heat exchangers and evaporations that are used in high sulfur flue gas The device and other equipment are used to resist the dew point corrosion of sulfur-containing flue gas.

The production of our seamless pipes is tightly regulated and all of the pipes we stock have been fully tested to international standards to ensure we only supply the highest quality products.

| Product name | Executive standard | Dimension (mm) | Steel code/ Steel grade |

|---|---|---|---|

| Black and Hot-dipped Zinc-coated Steel Pipes Seamless | ASTM A53 | 0.3-1200 x 1.0-150 | GR.A, GR.B, GR.C |

| Seamless Carbon Steel for High Temperature Service | ASTM A106 | 10.3-1200 x 1.0-150 | GR.B, GR.C |

| Seamless Cold-drawn Low-Carbon Steel Heat-Exchanger and Condenser Tubes | ASTM A179 | 10.3-426 x 1.0-36 | Low Carbon Steel |

| Seamless Carbon Steel Boiler Tubes for High Pressure | ASTM A192 | 10.3-426 x 1.0-36 | Low Carbon Steel |

| Seamless Cold-drawn Intermediate Alloy Steel Heat-exchanger and Condenser Tubes | ASTM A199 | 10.3-426 x 1.0-36 | T5, T22 |

| Seamless Medium-carbon Steel Boiler and Superheater Tubes | ASTM A210 | 10.3-426 x 1.0-36 | A1, C |

| Seamless Ferritic and Austenitic Alloy Steel Boiler, Superheater and Heat-exchanger Tubes | ASTM A213 | 10.3-426 x 1.0-36 | T5, T5b, T9 , T11, T22 ,T91 |

| Seamless Carbon and Alloy Steel for Mechanical Tubing | ASTM A333 | 1/4"-42" x SCH20-XXS | Grade1 Gr. 3,Gr..6, Gr.8 , Gr. 9 |

| Seamless Cold-drawn Carbon Steel Feedwater Heater Tubes | ASTM A556 | 10.3-426 x 1.0-36 | A2, B2 |

| Round and shaped steel cold formed welded and seamless carbon steel structural pipe. | ASTM A500 | OD :10.3-820 x 0.8- 75 | Grade A, B, C, D |

| Carbon and alloy steel mechanical tubing, either hot-finished or cold-finished | ASTM A519 | 10.3-426 x 1.0-36 | 1020, 1025, 4130, 4140 |

| For seamless ferritic alloy-steel pipe for high-temperature service | ASTM A335 | 1/4"-42" x SCH20-XXS | A/SA 335 P1, P2, P11, P12, P15, P22, P91, P92, P122 |

Cold Drawn Seamless Mechanical Tubing (CDS) is a cold drawn 1018/1026 steel tube which offers uniform tolerances, enhanced machinability and increased strength and tolerances compared to hot-rolled products.

Cold drawn steel tube is with hot-rolled steel coil as raw material, and tandem cold rolling pickled to remove oxide scale, its finished rolling hard roll, rolling hard volumes due to the continuous cold deformation caused by cold hardening strength, hardness increased indicators declined tough plastic, stamping performance will deteriorate, which can only be used for simple deformation of the parts.

Rolling hard roll can be used as the raw material of the hot-dip galvanizing plant, hot dip galvanizing line set annealing line. Rolling hard roll weight is generally 6 to 13.5 tons, the coil diameter of 610mm.

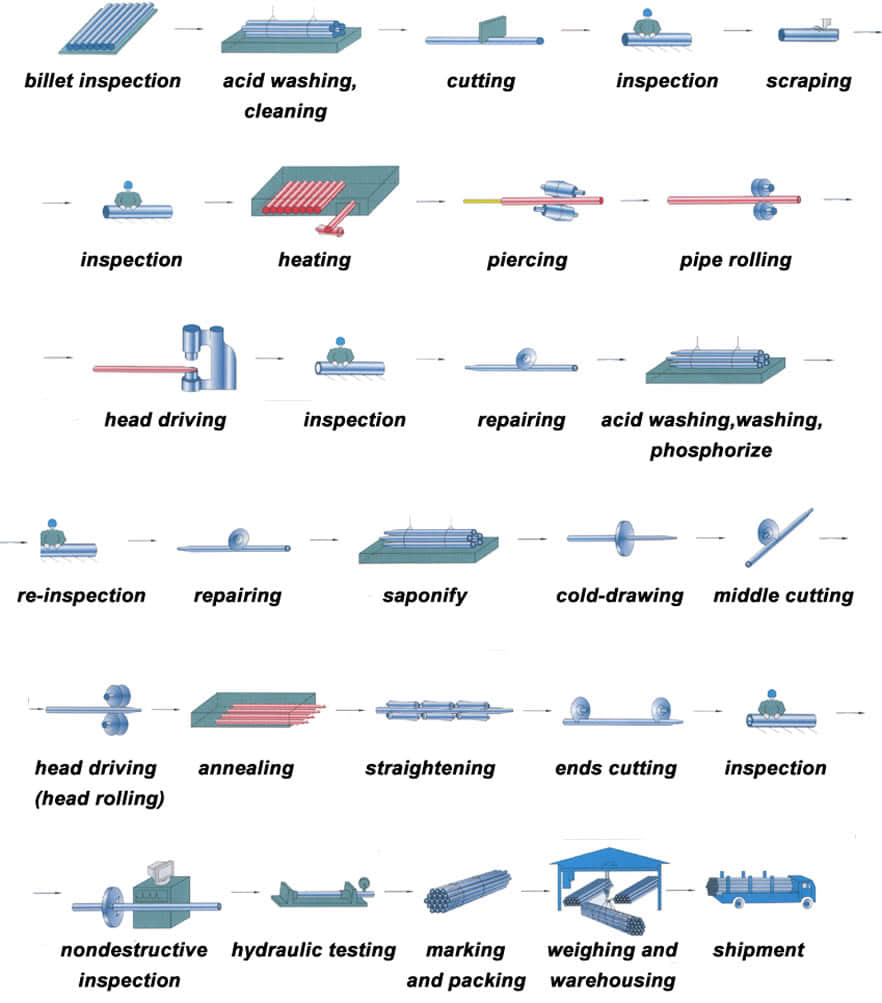

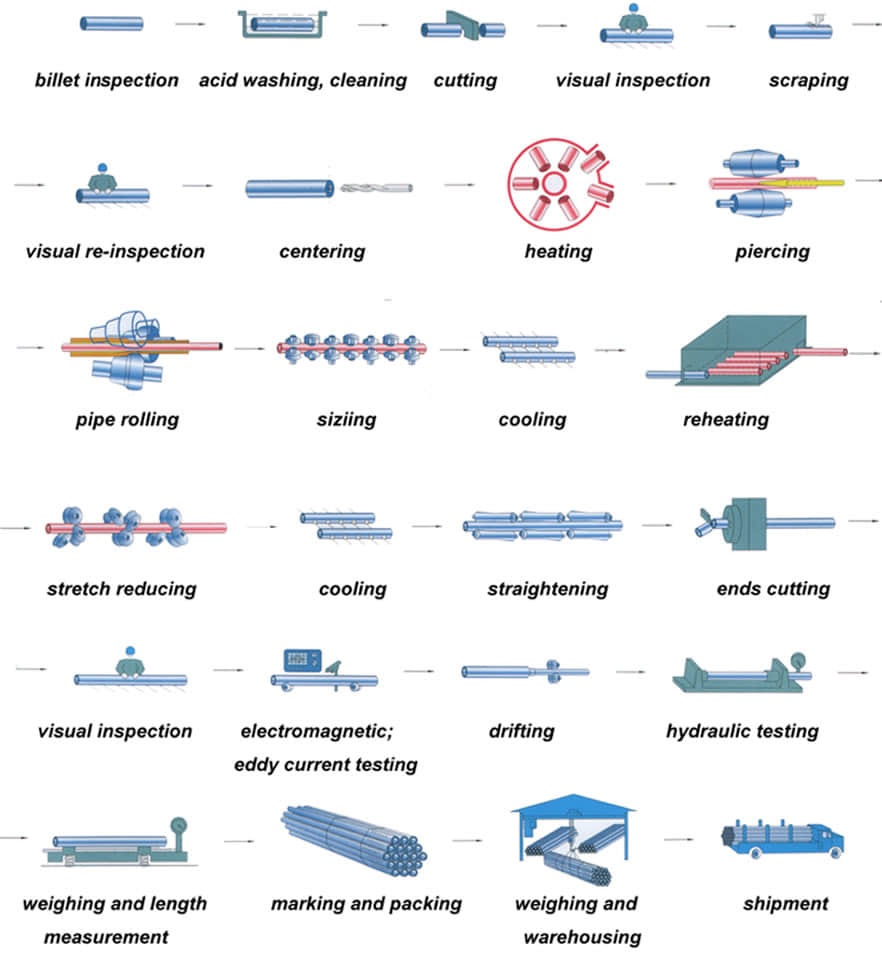

Hot-rolled seamless steel pipe production base deformation process can be summarized as three stages: perforation, extension and finishing.

The main purpose of the perforation process is to become a solid round billet piercing hollow shell. Capillary in the specifications, accuracy and surface quality can not meet the requirements of the finished product, further improvements are needed to deform the metal through. The main purpose of the stretching machine is further reduced sectional view (main compression wall) for a larger axial extension, so that the capillary improved dimensional accuracy, surface quality and organizational performance.

After stretching machine rolled steel pipe shortage collectively need further molding mill in order to achieve the requirements of the finished pipe. Rolled steel due to pass in the method widely used in the production of seamless steel tubes.

So far, due to the method pass rolling steel can be divided into two categories: core pension without rolling rolling (hollow body rolling), and with the mandrel. Sizing machines, reducing mill and stretch reducing mill belonging to the hole without mandrel type continuous rolling mills are generally coffin. Its main purpose is to reduce the diameter of the deformation process or sizing get finished steel, the wall thickness of process control, can make thinning, thickening or nearly unchanged.

All the traditional hole-type rolling machine with mandrel belong to extend machine. The main purpose is to reduce the deformation process perforated capillary wall thickness and outer diameter roll passes in the deformation zone and the mandrel posed, for a larger axial extension. At the same time a certain improvement in the organization, performance, accuracy, surface quality.

Before cutting pipe and tubing

No matter the material, measure the diameter of the pipe or tube to be cut to ensure that you use the right-size tube cutter for the job. When determining how to make a straight cut, use a tape measure and a pencil or other writing instrument to mark on the surface where you want to cut. If possible, mark around the circumference of a pipe, especially when cutting with a handsaw. Ensure that a cut is as straight as possible by securing the pipe with a vise, clamp, miter box or even duct tape to keep the length from shifting out of place while cutting.

After cutting pipe and tubing

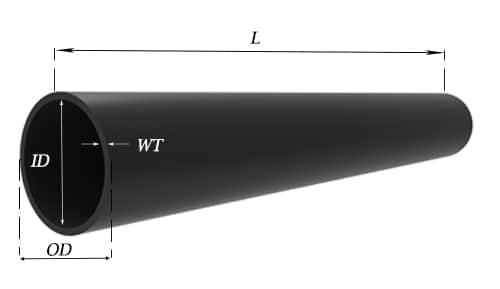

Geometrical inspection of steel pipes The outer diameter, wall thickness, bending and length of the steel pipe can be inspected on the inspection table with an outer caliper, a micrometer and a bending ruler, and a length tape measure.

Take seamless steel pipe as an example, there are some tolerances that affect quality. Noting this, and you will get a better pipe.

Weight tolerance

For pipe NPS 12 (DN300, 323.8mm) and under, the weight shall vary within -3.5% / +10%.

For pipe over NPS 12 (DN300, 323.8mm), the weight shall vary within -5% / +10%.

Pipe of NPS 4 (DN100, 114.3mm) and smaller may be weighed in convenient lots; pipe in sizes larger than NPS 4 shall be weighed separately.

Quantity tolerance

Normally mills take -10% to +10% tolerance, but TPMCSTEEL keeps ±3% variation.

Length tolerance

For Seamless pipe& tube, if definite cut lengths are ordered, the length shall vary within -0mm / +6mm.

| Pipe types | Pipe Szie(mm) | Tolerances | |

|---|---|---|---|

| Hot rolled | OD | <50 | ±0.50mm |

| ≥50 | ±1% | ||

| WT | <4 | ±12.5% | |

| ≥4-20 | +15%, -12.5% | ||

| >20 | ±12.5% | ||

| Cold drawn | OD | 6-10 | ±0.20mm |

| 10-30 | ±0.40mm | ||

| 30-50 | ±0.45 | ||

| >50 | ±1% | ||

| WT | <1 | ±0.15mm | |

| >1-3 | + 15%, – 10% | ||

| >3 | + 12.5%, – 10% | ||

| Standard | Hot finished seamless tube | Cold flnished seamless tube | ||

|---|---|---|---|---|

| Out diameter (mm) | Tolerance | Out diameter (mm) | Tolerance | |

| EN10216-1 | ≤100 | +/-0.75% (min.+/-0.5mm) | All | +/-0.5% |

| EN10216-2 | (min. +/-0.30mm) | |||

| DIN17175 | >100 | +/-0.90% | ||

| GB/T 3087 | ≤460 | +/-0.75% (min.+/-0.5mm) | 10-30 | +/-0.40mm |

| >30-50 | +/-0.45mm | |||

| >50 | +/-1.0% | |||

| GB/T 5310 GB/T 9948 GB/T 6479 | <57 | +/-0.40mm | ≤30 | +/-0.20mm |

| 57-325 | +/-0.75% | >30-50 | +/-0.30mm | |

| >325-460 | +1%,-2mm | >50 | +/-0.8% | |

| ASME SA-179M ASME SA-192M ASME SA-209M ASME SA-210M ASME SA-213M JIS G 3461 JIS G 3461 | ≤101.6 | +0.4, -0.8mm | <25.4 | +/-0.10mm |

| >25.4-38.1 | +/-0.15mm | |||

| >38.1-50.8 | +/-0.20mm | |||

| 101.6-190.5 | +0.4, -1.2mm | >50.8-63.5 | +/-0.25mm | |

| >63.5-76.2 | +/-0.30mm | |||

| >76.2 | +/-0.38mm | |||

| ASME SA106 ASME SA335 | ≤48.3 | +/-0.40mm | ≤48.3 | +/-0.40mm |

| 48.3-114.3 | +/-0.79mm | |||

| 114.4-219.1 | +1.59, -0.79mm | |||

| 219.2-323.9 | +2.38, -0.79mm | >48.3 | +/-0.79mm | |

| >324 | +/-1.0% | |||

| Standard | Hot finished seamless tube | Cold flnished seamless tube | ||||

|---|---|---|---|---|---|---|

| DIN17175 | Out diameter OD(mm) | Wall thickness T(mm) | Tolerance | Out diameter (mm) | Wall Thickness T(mm) | Tolerance |

| ≤130 | S≤2Sn | +15%, -10% | -- | All | +/-10% (min. +/-0.2mm) |

|

2Sn| +12.5%, -10% |

| |||||

| S>4Sn | +-/9% | |||||

| >130 | S≤0.05da | +17.5%, -12.5% | ||||

0.05da| +/-12.5% |

| |||||

| S>0.11da | +/-10% | |||||

| EN 10216-1 EN 10216-2 | ≤219.1 | - | +/-12.5% (min.+/-0.4mm) |

|||

| -- | T/D≤0.025 | +/-20% | ||||

0.025| +/-15% |

| |||||

0.05| +/-12.5% |

| |||||

0.1| +/-10% |

| |||||

| GB/T 3087 | -- | ≤20 | +15%,-12.5% (min.+0.45, -0.35mm) | -- | 1.0-3.0 | +15%, -10% |

| >20 | +/-12.5% | -- | >3 | +12.5%, -10% | ||

| GB/T 5310 GB/T 9948 GB/T 6479 | -- | <4.0 | +15%,-10% (min.+0.48, -0.32mm) | -- | 2-3 | +12%,-10% |

| 4-20 | +12.5%,-10% | >3 | +/-10% | |||

| >20 | +/-10% | |||||

| ASME SA-179M ASME SA-192M ASME SA-209M ASME SA-210M ASME SA-231M JIS G 3461 JIS G 3462 | -- | 2.41-3.8 | +35%, -0% | ≤38.1 | -- | +20%,-0% |

| 3.8-4.6 | +33%,-0% | >38.1 | -- | 22%,-0% | ||

| >4.6 | +28%,-0% | -- | -- | -- | ||

| ASME SA-106 ASME SA-335 | -- | All | +/12.5% | All | +/-10% | |

Note:

Positive material identification (PMI) testing is the examination of a material, usually a metallic alloy, to confirm the material is consistent with the user’s request.

Steel pipe delivery status(condition): cold / hard (BK), cold / soft (BKW), after cold stress relief annealing (BKS), annealing (GBK), normalized (NBK).

| Term | Symbol | Explanation |

|---|---|---|

| Cold-finished/hard (cold-finished as-drawn) | BK | No heat treatment after the last cold-forming process. The tubes therefore have only low deformability. |

| Cold-finished/soft (lightly cold-worked) | BKW | After the last heat treatment there is a light finishing pass (cold drawing) With proper subsequent processing, the tube can be cold-formed (e.g. bent, expanded) within certain limits. |

| Annealed | GBK | After the final cold-forming process the tubes are annealed in a controlled atmosphere or under vacuum. |

| Normalized | NBK | The tubes are annealed above the upper transformation point in a controlled atmosphere or under vacuum. |

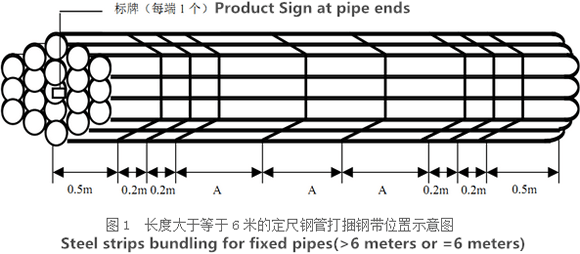

There are probably hundreds of different methods for packing a pipe, and most of them have merit, but there are two principles that are vital for any method to work prevent rusting and Sea transportation security.

Our packing can meet any needs of the customers.

Need to inquire about our products? Fill out the form below and our staff will be in touch!

Q: How long is your delivery time?

A: The delivery time of customized products is generally 25 35 days, and non customized products are generally shipped within 24 hours after payment.

Q: Do you provide samples? Is it free?

A: If the value of the sample is low, we will provide it for free, but the freight needs to be paid by the customer. But for some high value samples, we need to charge a fee.

Q: What are your payment terms?

A: T/T 30% as the deposit,The balance payment is paid in full before shipment

Q: What is the packaging and transportation form?

A: Non steaming wooden box and iron frame packaging. Special packaging is available according to customer needs. The transportation is mainly by sea.

Q: What is your minimum order quantity?

A: There is no minimum order quantity requirement. Customized products are tailor made according to the drawings provided by the customer.